AI Failure Detection in 3D Printing

Introduction

The technology of 3D printing has revolutionized the manufacturing process by enabling the production of intricate designs and personalized parts with relative ease of operation. However, like all technologies, 3D printing has its fair share of challenges. Print failure is one of the most significant, leading to material waste as well as a loss of time and money.

Fortunately, advanced artificial intelligence (AI) systems have come up with new techniques for early detection and prevention of such failures, which can be done by alerting users, modifying the print depending on the intensity of the error, or even stopping it completely before wasting more resources. Here we will go through some AI-based failure detection solutions for 3D printing provided by Obico, Bambu Lab, Creality, Octoprint Nexus AI, and OctoEverywhere.

Some of these tools are closed systems tied to specific printers, like Bambu Lab and Creality AI solutions, while others are open-source software that works on many different 3D printers, such as Obico.

Before we get started, let’s first understand what AI is, its role in 3D printing failure detection, and how it works.

AI, or artificial intelligence, refers to the simulation of human intelligence in machines that are programmed to think and learn like humans. In the context of 3D printing, AI can analyze vast amounts of data from the printing process in real time. By doing so, it can detect patterns and anomalies that may indicate a potential failure. These AI systems use machine learning algorithms, which are trained on large datasets of both successful and failed prints. This training involves thousands of labeled images to generate an accurate dataset for a specific AI model. The AI then compares the real data from sensors like cameras or LiDAR (during printing) with the trained data to recognize these errors.

When an AI system detects a potential issue, it can take various actions, depending on the software configuration. For instance, it might alert the user via a mobile app notification, email, SMS, or another messaging platform. In more advanced systems, the AI can even pause the print job or make adjustments on the fly to correct the issue. If a catastrophic error is detected, the AI can stop the printer entirely to prevent further damage or waste. This proactive approach helps to minimize waste and increase the success rate of 3D printing projects.

Now, let's delve into the specifics and features of each AI-driven failure detection solution, starting with the most advanced and widespread one Obico!

AI-Based 3D Printer Failure Detection with Obico

Obico (formerly The Spaghetti Detective) was the first in the 3D printing market to offer an AI-based failure detection system with high reliability. Its AI-failure detection system is the most comprehensive and effective in this industry. To function effectively, AI systems require large datasets. With its massive database, Obico leads the market. As of the time of writing this article, Obico has monitored over 89.8 million hours of 3D printing, detected 1,067,608 failed prints, and saved over 23,487 kilograms of filament. You can always follow these real-time statistics through this link.

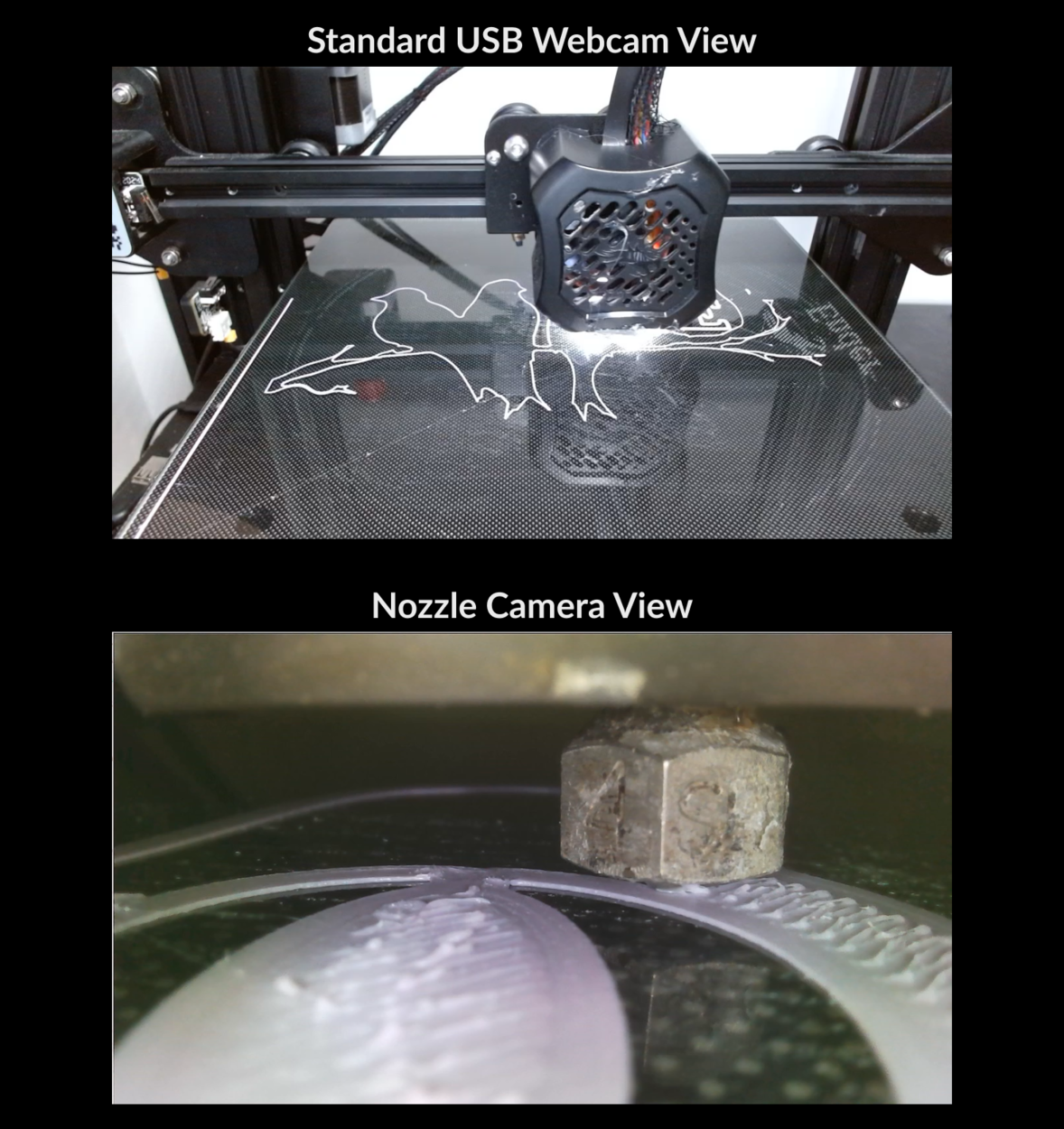

Obico offers two primary systems for AI detection. The first is a general system that monitors the entire printed part, while the second, Nozzle Ninja, focuses specifically on the critical first layer of the print. Both systems leverage advanced AI algorithms and large datasets to predict and detect failures, ensuring high-quality prints and minimizing waste.

Before delving into the specifics of each system, it's important to understand the broader context of Obico and the array of features it provides.

What is Obico and its features?

Obico is a cutting-edge open-source and AI-powered platform designed to enhance the 3D printing experience by offering comprehensive failure detection, remote monitoring, and control. Initially launched as The Spaghetti Detective, Obico has evolved to become a trusted tool for over a hundred thousand makers, catching over a million failed 3D prints and significantly reducing material waste.

Obico integrates seamlessly with Klipper and OctoPrint, allowing users of these platforms to access its powerful features with ease. When used with Klipper, Obico supports access to the Mainsail and Fluidd interfaces, enabling comprehensive control over Klipper features and configurations from the same interface.

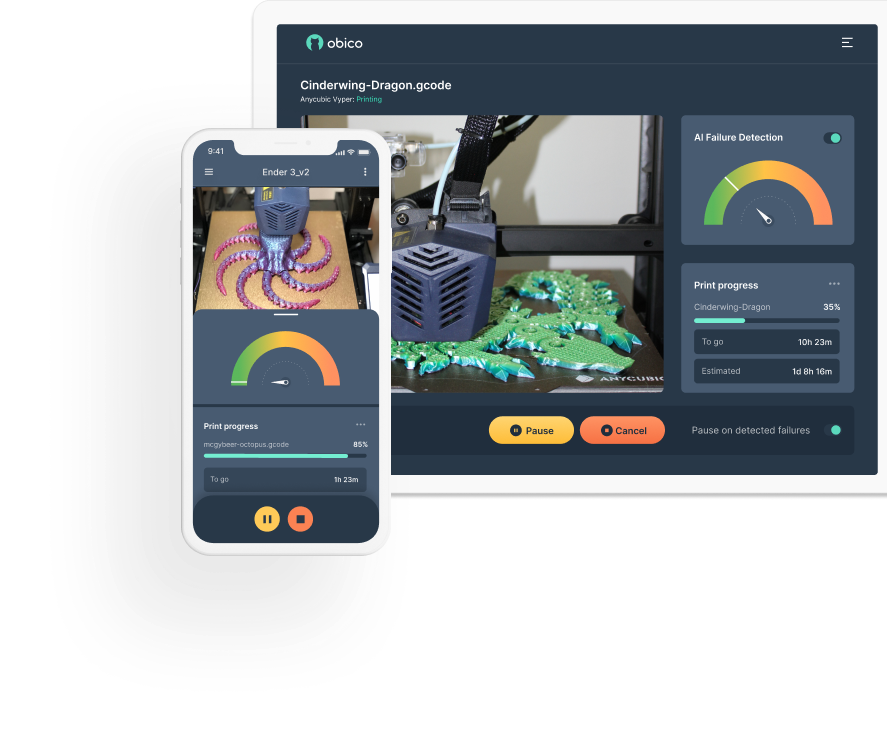

Through Obico, users can manage their 3D printers from any device, receiving real-time updates on print status and the ability to start, pause, resume, cancel print jobs, or move the printer head and bed while watching the printer live through the connected camera. Obico also provides detailed print analytics and history, including print duration, filament usage, and success rates, helping users understand their printer's performance and optimize their printing process. Additionally, it offers a terminal where users can send direct G-code commands to the printer and receive a reply.

More features about Obico:

Alerts and notifications

Obico can send notifications via email, SMS, Discord, pushbullet, Pushover, Slack, telegram, or mobile app when a print starts, finishes, or encounters an issue. Users have the ability to customize these alerts based on their preferences.

Remote Print Job Management

Users can start, pause, resume, or cancel print jobs remotely from anywhere in the world, without needing to be connected to the same local network.

Cloud and Local Server Options

Users can choose to run Obico in the cloud for easy access from anywhere or set up their own local server for more control, customization options, and privacy.

Wide printers and boards support

Obico supports a wide range of printers, including many that come pre-installed with Klipper, such as:

- Kingroon KLP1

- Kingoon KP3S Pro V2

- Biqu Huraken

- Qidi Tech X-Smart 3

- Qidi Tech X-Plus 3

- Qidi Tech X-Max 3

- Sovol SV06

- Sovol SV06 Plus

- Sovol SV07

- Sovol SV07 Plus

- Elegoo Neptune 4

- Elegoo Neptune 4 Pro

- Elegoo Neptune 4 Max

- Creality K1

- Creality K1 Max

We offer detailed guides for each of these printers. If you own one and want to give Obico a try, simply click on the printer’s link and follow the dedicated step-by-step guide.

Additionally, Obico is compatible with open-source printers like the Voron 2.4 and printers with Makerbase boards that come with pre-installed Klipper. So even if your printer is not listed in our guides, but it has a Makerbase board with Klipper installed, you can just follow our guide here: Install Obico for Makerbase 3D printer.

And if you are using an open-source Klipper 3D printer like Voron 2.4, you can follow this general guide here: Set up Obico for Klipper.

Now that we have looked at Obico and its features, let’s delve deeper into Obico’s two primary systems for AI detection.

Obico’s General AI Detection System

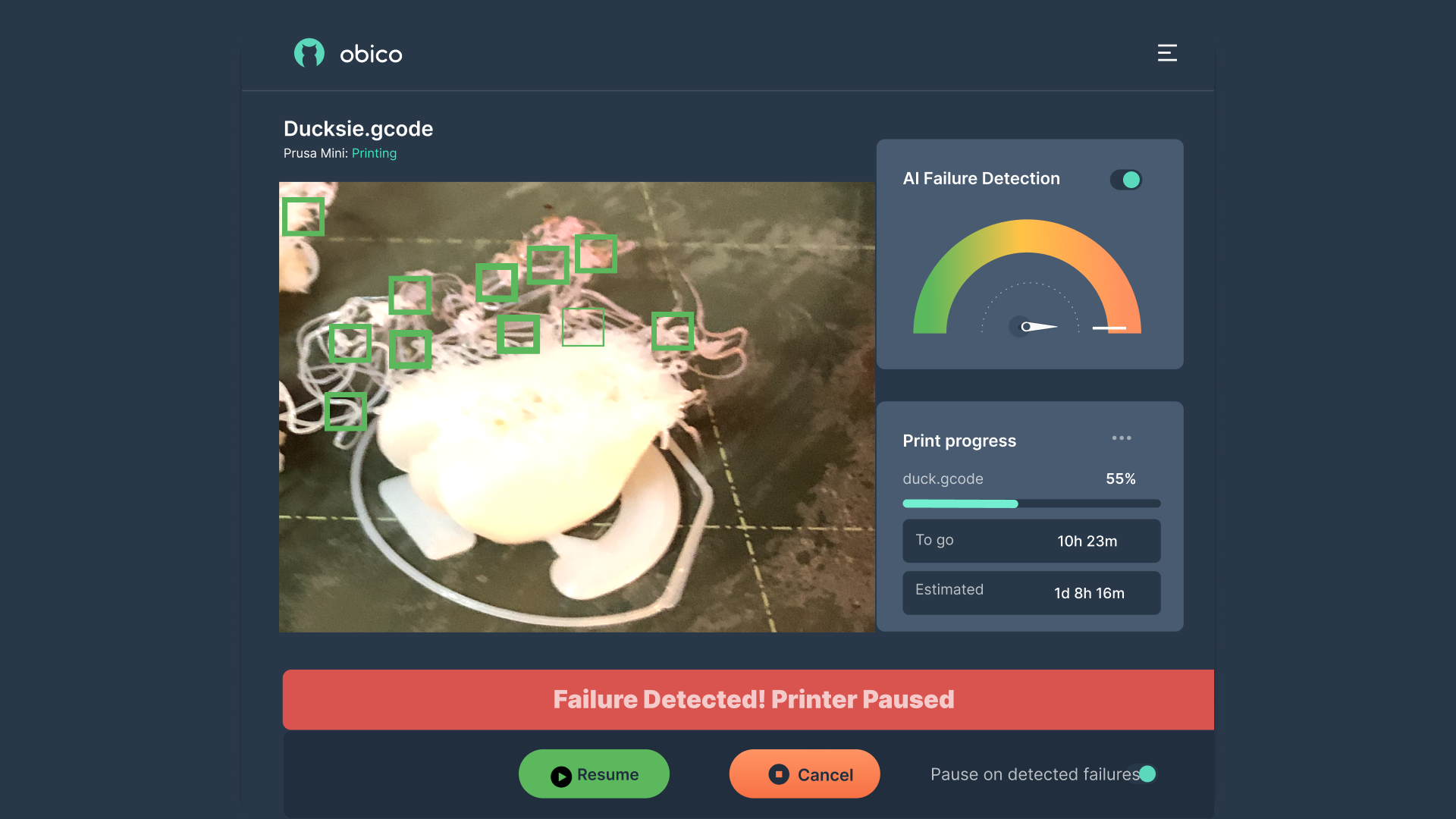

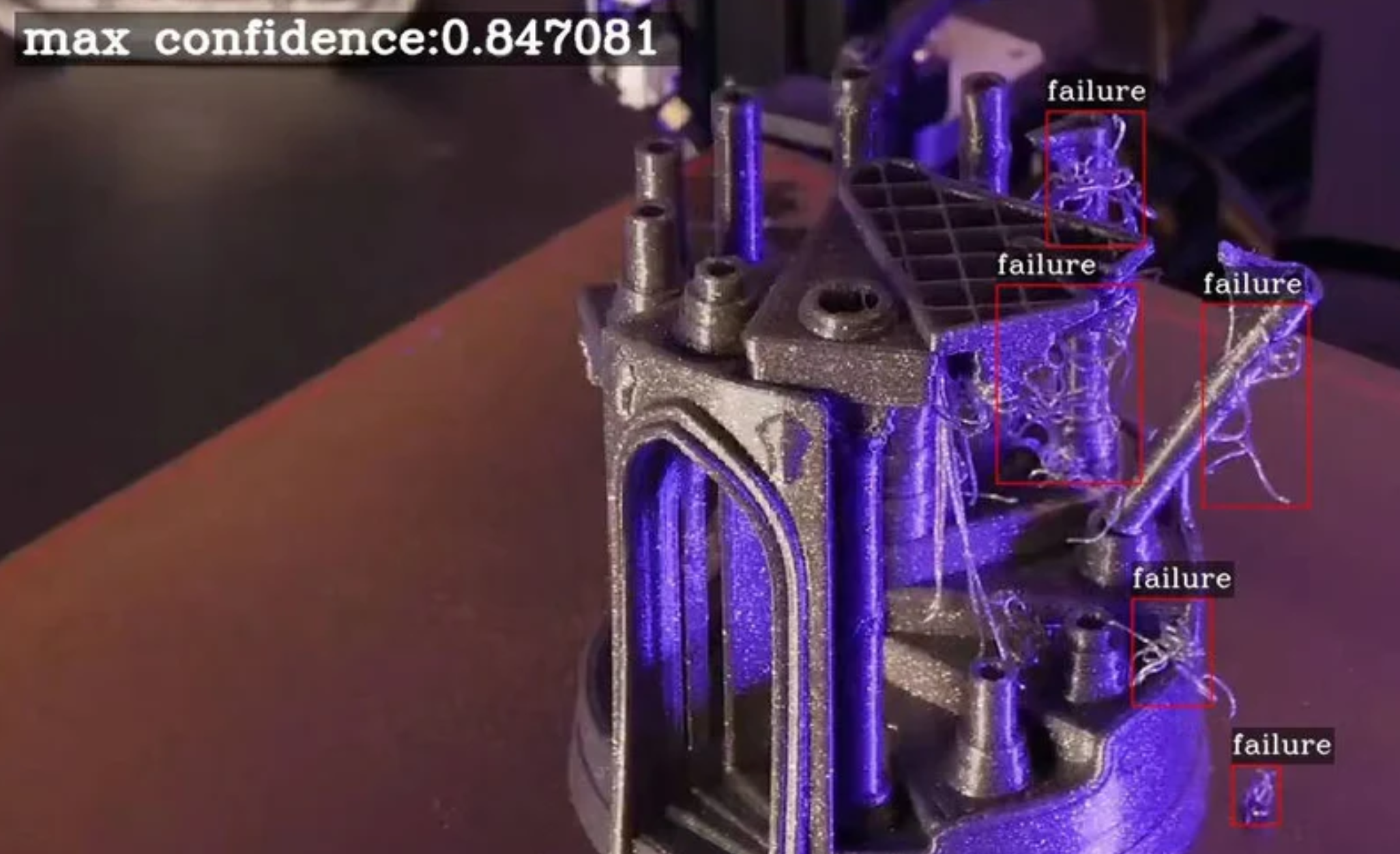

The general AI detection system in Obico monitors the entire printed part. It uses a camera to capture images of the print at regular intervals during the printing process, which are then analysed by machine learning algorithms trained on a vast dataset of successful and failed prints. This system can detect common issues, such as spaghetti monsters. Upon detecting a potential problem, the system can alert or take corrective actions, such as pausing the print to prevent further damage or waste.

There is an option at Obico to pause on detected failures, and you can turn it on or off.

As we mentioned before, Obico is designed with user-friendliness in mind, making it easy to navigate and operate. Through the camera feed section in the Obico app, users can view a real-time video stream of their printing process. The system highlights any potential failures with green labels, making them easy to spot.

Additionally, there is a dynamic real-time meter with three colored sections (green, yellow, and red) that indicate the percentage or level of potential failure, providing users with a clear visual representation of any issues as they arise.

This intuitive interface ensures that users can easily monitor and manage their prints, enhancing the overall 3D printing experience and reducing the likelihood of failed prints.

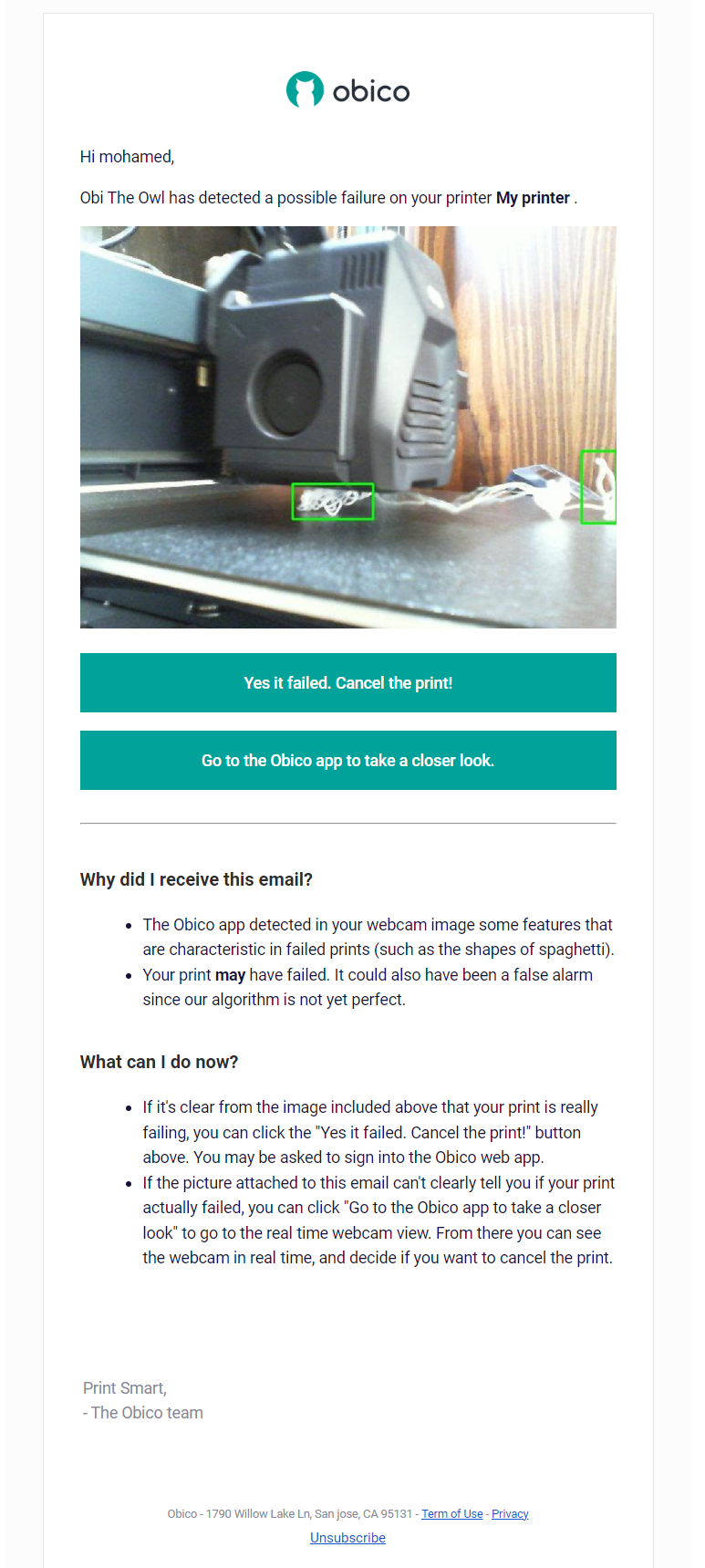

If Obico finds a problem, it will send you notifications in different ways, depending on how you set it up. You can get emails, push notifications on your phone, and alerts through various apps. Each notification will include a picture and details about the problem. This way, you know immediately if something goes wrong and can take action to fix it.

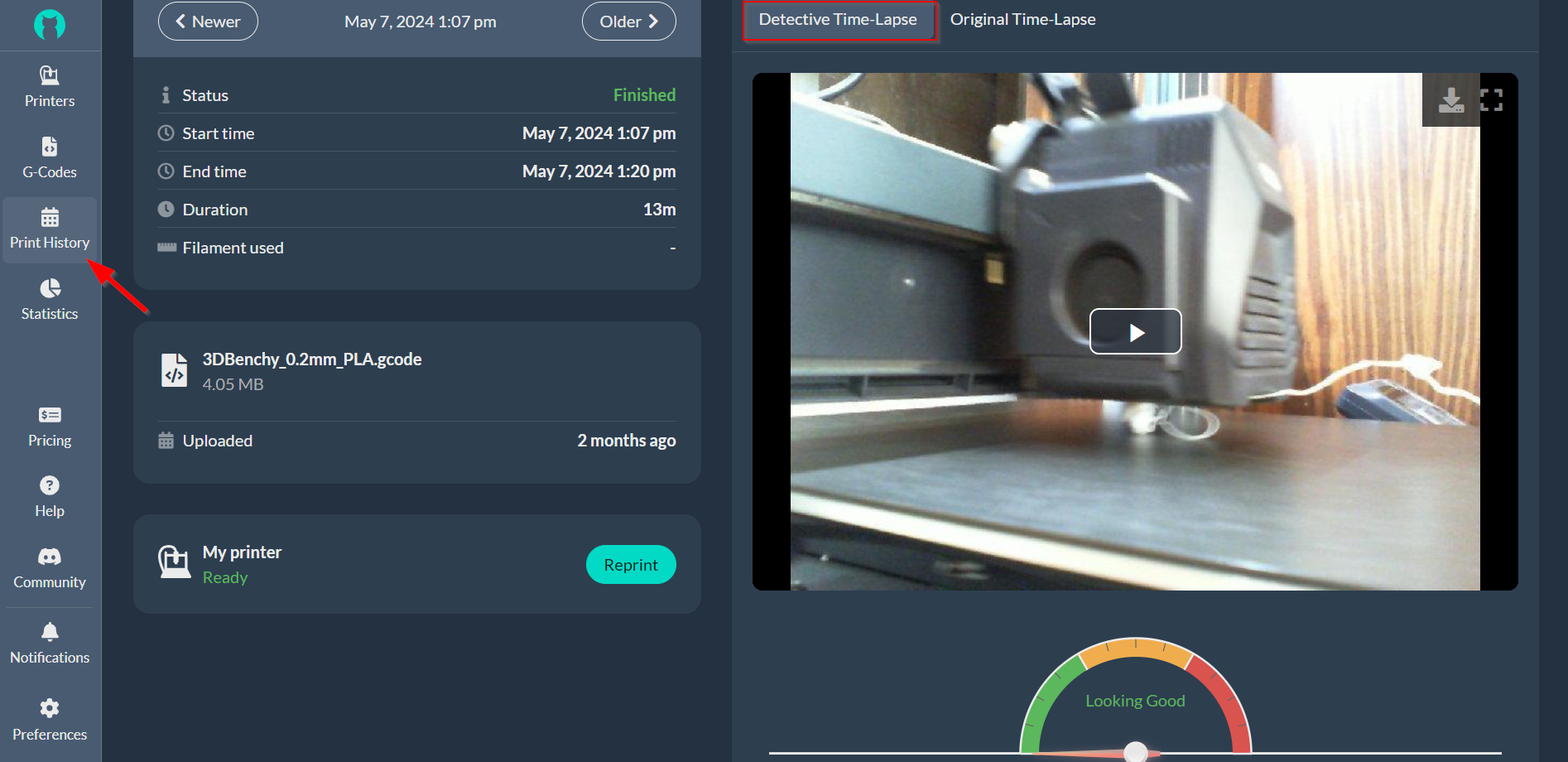

Obico also provides you with time-lapse videos of your prints. These are accessible from the Print History tab and can be viewed directly or downloaded to your device. You can choose the Detective version, which reviews the AI at work again with the AI meter, highlighting parts that it thinks may be a print failure. This feature provides a visual record of your prints, allowing you to review and learn from each printing session. Additionally, you can send feedback about the AI detection system's performance, helping Obico improve its accuracy and performance.

Obico’s Nozzle Ninja - First Layer AI Detection System

At Obico, our team is always working on developing and testing new technologies to make 3D printing easier and more convenient for users and hobbyists. So, Obico introduces the new and most exciting technology: Nozzle Ninja!

The first layer of a 3D print is one of the most critical parts of the entire process. If the first layer isn't perfect, the rest of the print is likely to fail. That's why Obico developed Nozzle Ninja, an advanced AI system designed specifically to ensure the first layer is flawless.

The importance of the first layer cannot be overstated. It's like the foundation of a building; if it's not strong and properly laid out, everything built on top of it will be unstable. Problems in the first layer, such as poor adhesion to the print bed or uneven extrusion, can lead to print failures like warping or detachment from the bed. Recognizing these challenges, Nozzle Ninja provides a solution focused on detecting and correcting these issues before they escalate.

Nozzle Ninja operates differently from traditional webcam-based AI systems that monitor the entire print. It uses a dedicated nozzle camera, mounted close to the nozzle, to provide a detailed view of the first layer as it's being printed with a flash light for better contrast. This close-up perspective allows the AI to detect issues that would be hard to see with a regular webcam in the other general system.

Setting up Nozzle Ninja involves installing a compatible nozzle camera, such as the Mintion Nozzle Camera or the 3DO Nozzle Camera. Once installed, the camera monitors the first layer, looking for common issues like under-extrusion, over-extrusion, bed adhesion problems, warping, bubbling, and nozzle blobbing.

After the first layer is complete, Nozzle Ninja analyzes the data and sends a report. This report can be viewed in several ways. In the Obico web or mobile app, users can view a detailed report of the first layer, including an AI timelapse that shows what went wrong and when.

Additionally, users receive an email with the report. Each report includes a grade for the first layer (A–F) with detailed analysis and improvement suggestions. It also sends instant push notifications on your phone, providing a snapshot and grade of the first layer, ensuring that you are aware of any issues as soon as they occur, even if you're not near your printer.

One of the standout features of Nozzle Ninja is its layer scan capability for Klipper users. In addition to collecting images while the first layer prints, users can configure a layer scan macro to have Obico's first layer AI scan the print after the first layer finishes, providing a better and more accurate analysis of the first layer as a whole.

The benefits of the Nozzle Ninja are significant. By catching issues in the first layer, it helps prevent wasted materials and time. The detailed analysis provided by the AI timelapse and reports offers clear insights into what went wrong, helping improve future prints. Real-time notifications ensure users are aware of any issues as soon as they occur, providing convenience and peace of mind.

Getting started with Nozzle Ninja is straightforward. After installing a compatible nozzle camera, users can follow the setup guides provided by Obico for either Klipper or OctoPrint printers. Implementing Nozzle Ninja can significantly enhance the reliability and quality of your 3D prints, ensuring that the all-important first layer is always perfect.

If Obico’s Nozzle Ninja caught your interest and you want to give it a try, you can find more details, guides, and videos through the following links:

With Obico, you can use both Obico’s general AI detection system and Nozzle Ninja together. By doing so, you will have complete control over your entire 3D printing process, from the first layer to the last. This means you can catch and fix problems right from the start with Nozzle Ninja, ensuring a perfect first layer, and then use the general AI system to monitor the rest of the print for any issues. Together, these systems help you produce high-quality prints with less waste and fewer failures, giving you peace of mind and saving you time and materials.

Now let’s talk about Bambu Lab AI failure detection.

Brief About Bambu Lab

Bambu Lab is a leading company in the 3D printing industry, known for integrating advanced AI features into their products. As we previously mentioned, their AI detection system is a closed system, specifically designed to work seamlessly with their 3D printers.

In this section, we will explore the AI capabilities of the Bambu Lab X1-Carbon printer as an example and learn how these features can enhance the printing experience.

AI-Powered Features of Bambu Lab X1-Carbon

The Bambu Lab X1-Carbon printer supports some AI features to ensure high-quality and reliable prints:

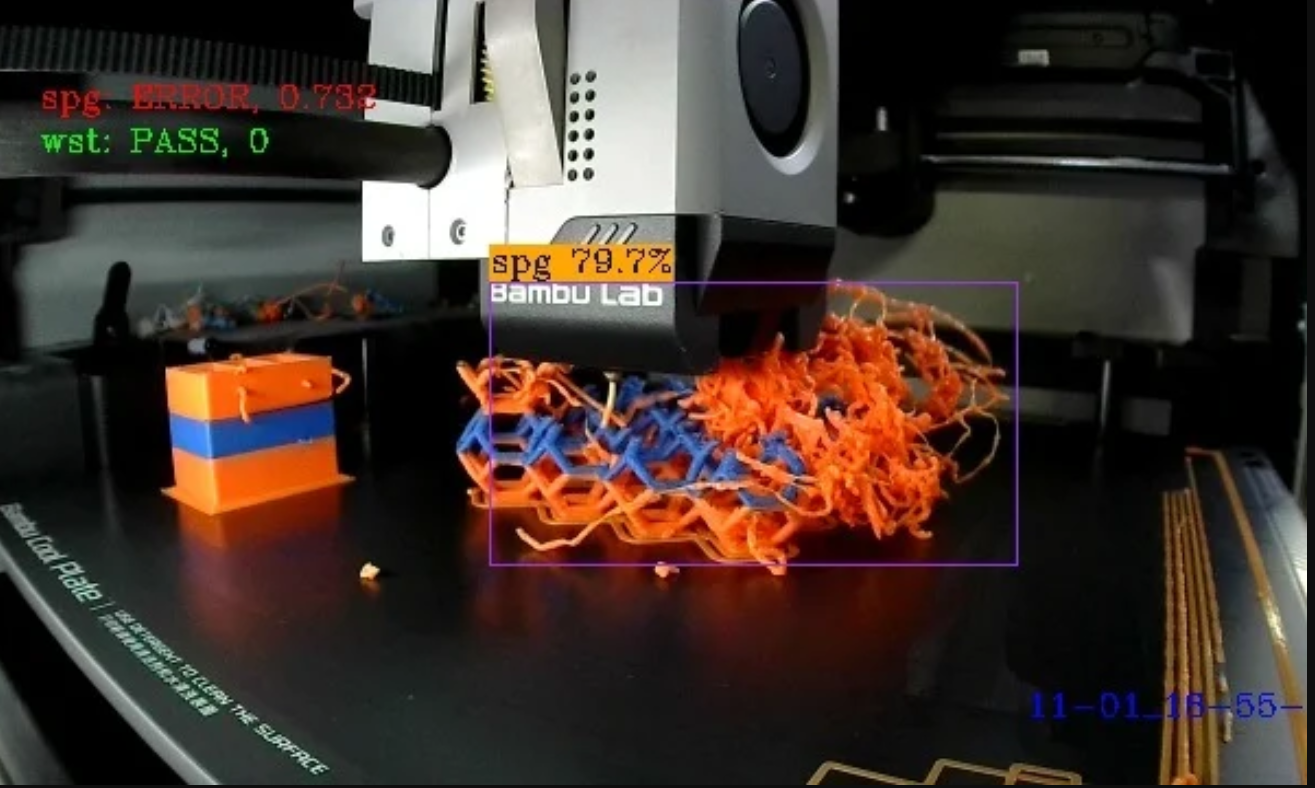

Spaghetti Detection is one of these standout features. The X1-Carbon is equipped with a USB camera installed in the corner of the print chamber, which monitors the printing process in real time. Every few seconds, the camera captures a frame, which is then analyzed by an AI detector running on the printer's Neural Processing Unit (NPU). This AI uses a state-of-the-art object detection neural network to identify potential "spaghetti" failures by evaluating the confidence level of detected anomalies. It accumulates the results for the latest 10 frames. If there are enough positive candidates, and they are spatially consistent, then a spaghetti failure is detected.

It’s worth noting that not all Bambu Lab models come equipped with the same AI features. While the X1-Carbon boasts built-in spaghetti detection and LiDAR capabilities, more budget-friendly options—like the A1 or P1 series—may not include these advanced functions by default. In these instances, relying on an external solution can be the perfect workaround. Follow our guide on AI Failure Detection for Bambu Lab 3D Printers to learn how to integrate Obico and unlock AI-driven failure detection and remote monitoring—even if your printer wasn’t originally designed for it.

source: wiki.bambulab.com

source: wiki.bambulab.com

If the confidence level surpasses a user-defined threshold (in the settings), the printer can pause to prevent further issues.

This feature works best with the chamber light on, ensuring optimal image quality for detection.

Bambu Lab X1C also comes with Micro Lidar technology that measures depth with micrometer precision. This system scans the print bed and the first layer of the print to ensure everything is correctly aligned. It adjusts the nozzle height, calibrates filament flow, and inspects the first layer for any irregularities. This precise measurement ensures that prints start correctly, reducing the likelihood of errors from the very beginning. The Micro Lidar also helps with bed leveling by providing precise measurements that are cross-verified by the printer’s dual sensor system.

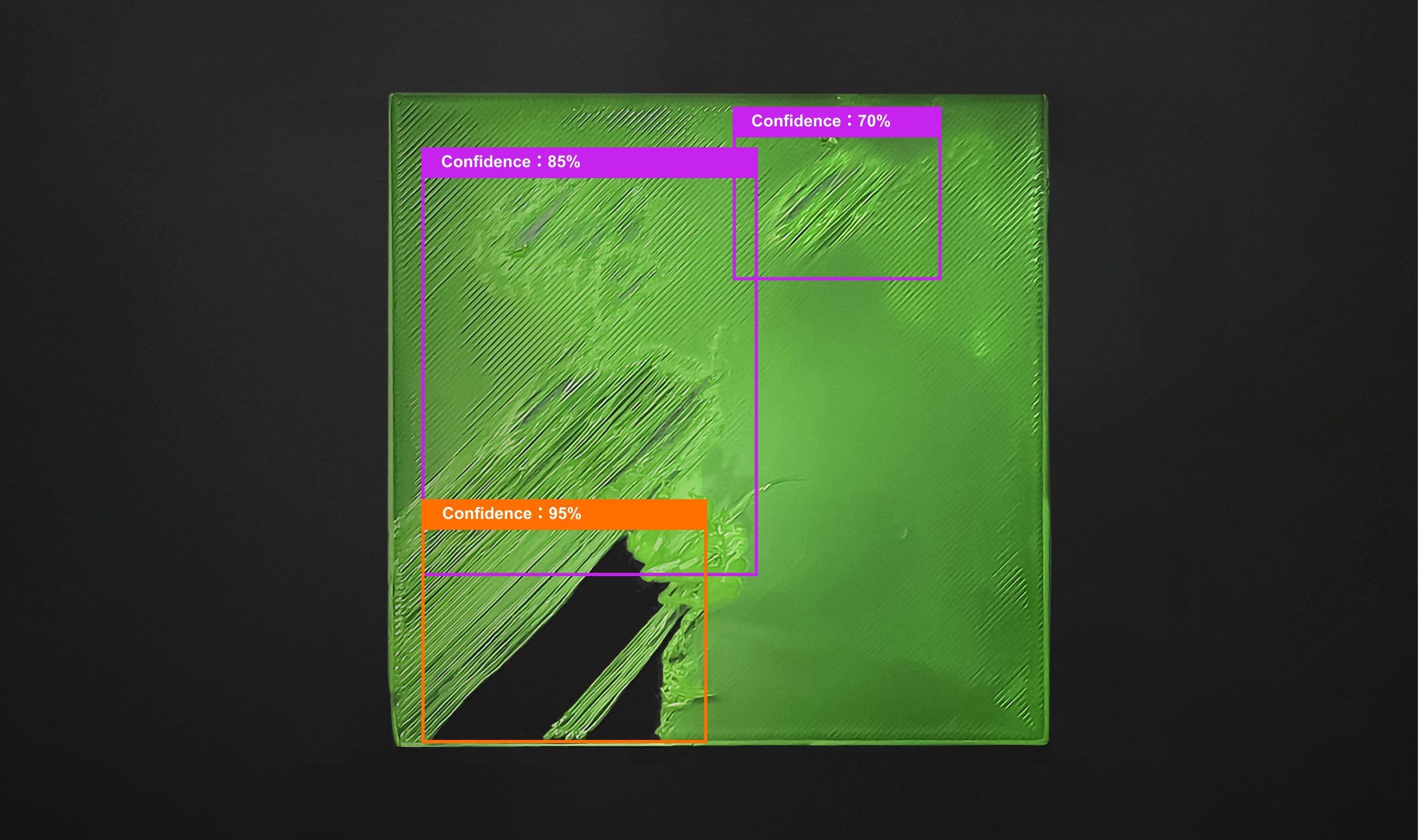

The next image shows the AI first layer inspection in Bambu Lab X1C, and as you can see, the purple label indicates that it is higher than the desired first layer height. The orange label indicates that it is lower than the desired first layer height. Each label is tagged with a confidence percentage for greater reliability.

source: wiki.bambulab.com

source: wiki.bambulab.com

Dual Auto Bed Leveling is another advanced feature of the X1-Carbon. This system uses two independent sensors: a Lidar sensor and an analog force sensor. These sensors measure the height of the nozzle relative to the bed, and an algorithm cross-checks the data to ensure the bed is perfectly level. This dual-sensor approach provides an extra layer of accuracy and reliability, crucial for achieving high-quality prints. The Lidar sensor scans the bed's surface at multiple points, while the force sensor ensures that the nozzle height is consistent across the bed.

Even when the printer operates in "LAN Only" mode without an internet connection, it still leverages local processing power to perform AI-driven tasks like Spaghetti Detection. However, connecting the printer to the cloud enhances its capabilities. Cloud connectivity allows the printer to receive regular AI model updates, improving detection accuracy and overall performance. Regular firmware updates are recommended to take full advantage of these improvements.

Bambu Lab encourages users to participate in the Experience Improvement Program. By joining this program, users' print data, including images and performance metrics, is automatically uploaded to the cloud. This data helps Bambu Lab refine their AI algorithms, reducing false alarms and enhancing detection capabilities over time. Participating in this program ensures that the AI model continues to learn and improve from a wide range of printing scenarios, benefiting all users.

AI-Assisted Failure Detection in Creality K1 Max

Creality is a well-known brand in the 3D printing industry, famous for producing affordable and reliable 3D printers. Like Bambu Lab, Creality has integrated advanced AI features into some of their products to enhance the printing experience.

Their AI system is a closed system designed specifically for certain Creality printers. Here, we'll explore the AI capabilities of the Creality K1 Max printer as an example to understand how these features can improve your 3D printing experience.

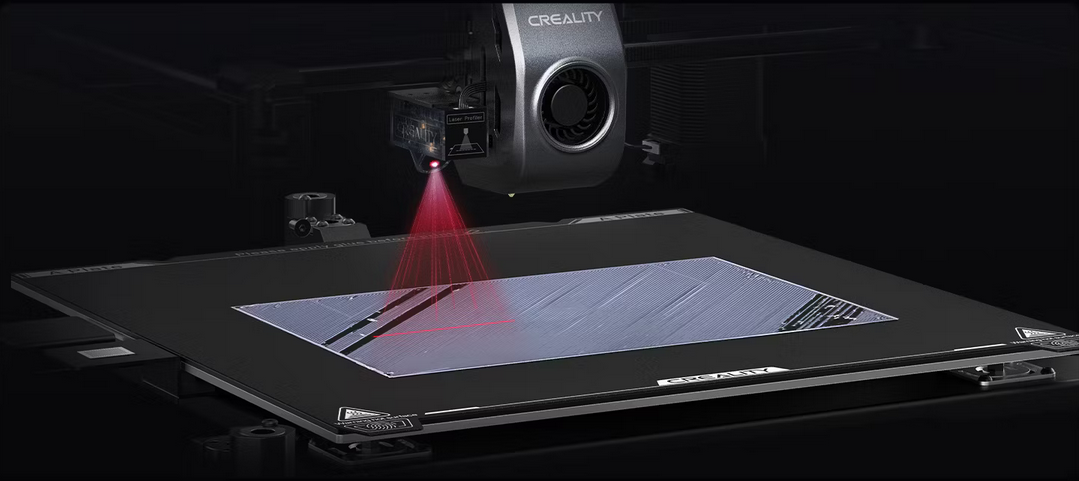

The Creality K1 Max offers AI-assisted, carefree printing with several advanced features to ensure high-quality prints. One of its standout features is the AI LiDAR, which takes care of the first layer of your print. This high-precision LiDAR, with a resolution of 1 μm, scans the first layer of the print. If it detects any issues, it will pause the printing process and notify you immediately. This ensures that any problems with the crucial first layer are addressed right away, preventing further issues down the line.

source: creality.com

source: creality.com

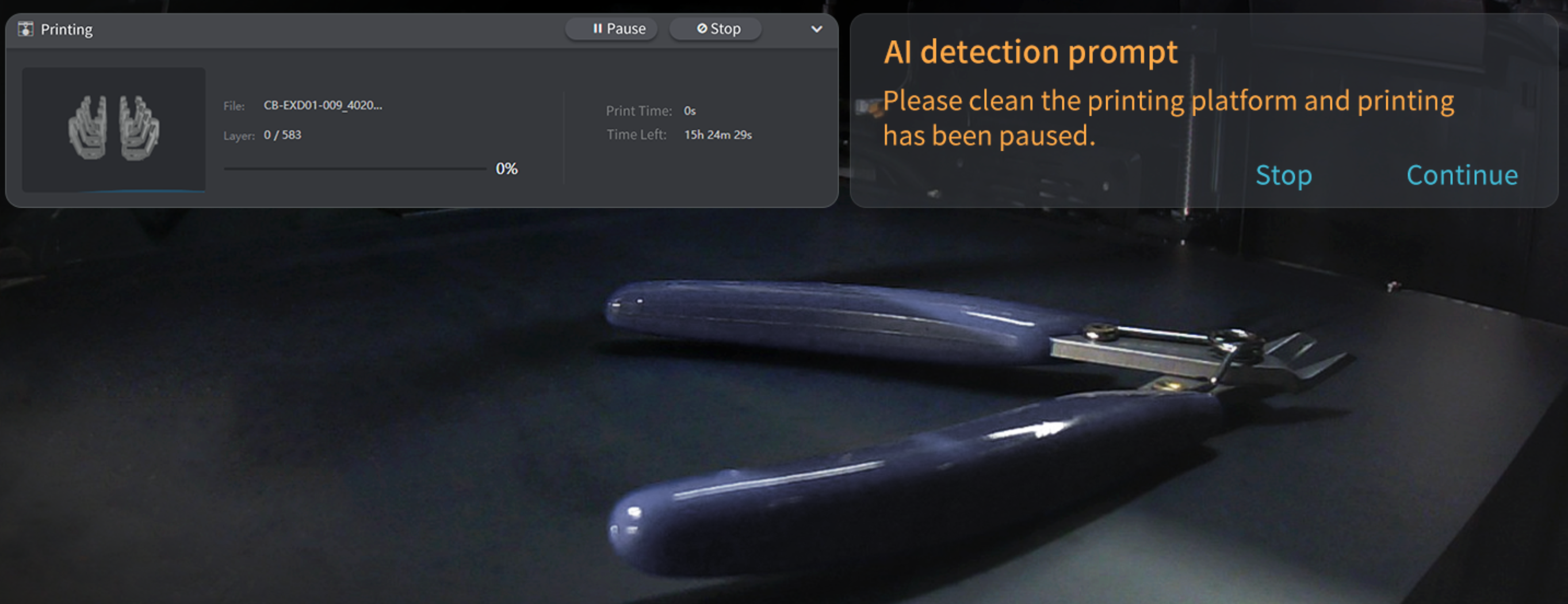

Additionally, the K1 Max uses an AI camera to keep a keen eye on the printing process. This camera is capable of detecting spaghetti failures, foreign objects, and debris. If an error occurs, the system will alert you or pause the printer, allowing you to take action to correct the problem. The AI camera also supports real-time monitoring, giving you the ability to check on your prints from the app, and it can create time-lapse videos of your prints, which can be shared with others and useful for troubleshooting.

source: creality.com

source: creality.com

These AI-driven features make the Creality K1 Max a powerful printer for achieving reliable and high-quality 3D prints, reducing the chances of failure, and saving both time and materials.

But as we mentioned, with these closed systems, you have limited customization options when compared with open-source ones like those at Obico.

OctoPrint Nexus AI Failure Detection

Nexus AI is a smart tool to detect 3D print failures. It was developed by Fiberpunk for use with the Sentry Pro camera. It has now been made available as an open-source plugin for OctoPrint (a popular platform for managing 3D printers). Fiberpunk aimed to make Nexus AI accessible to as many 3D printers and users as possible.

source: fiber-punk.com

source: fiber-punk.com

Nexus AI works by recognizing patterns in pictures uploaded by clients to detect 3D printing failures. It is easy to deploy; you just need to install a program on your old computer. Unlike cloud-based services, Nexus AI is safer as it runs on your local server, meaning your data does not need to be sent over the internet. It also has low hardware requirements and can run on machines without the latest high-power CPU or GPU. For enhanced performance, Nexus AI can use Intel’s OpenVINO for machine vision model acceleration.

The Nexus AI system consists of two parts: the OctoPrint plugin and the local server. The plugin captures images from OctoPrint-compatible cameras, while the server processes these images using machine learning algorithms to detect potential print issues. When a problem is detected, Nexus AI takes a photo and sends an email to notify the user. Fiberpunk plans to expand Nexus AI to work with other plugins, allowing notifications via apps or enabling users to take direct actions.

The main goal of Nexus AI is to make print failure detection available to as many users as possible. Fiberpunk has made the Nexus AI API open, encouraging other developers and teams to integrate it with their systems. This openness aims to foster a broader ecosystem of tools and plugins working together to improve 3D printing reliability.

Fiberpunk continues to develop and enhance Nexus AI, with plans to expand support to other platforms like Klipper.

However, while Nexus AI is a good tool, it is not as accurate as Obico. Obico's AI has been trained on massive datasets, giving it a higher level of precision in detecting print failures. Nexus AI, while effective and accessible, may not catch all issues as reliably as Obico, which benefits from extensive data and continuous improvement.

Lastly, let’s explore OctoEverywhere's AI capabilities.

OctoEverywhere AI failure detection

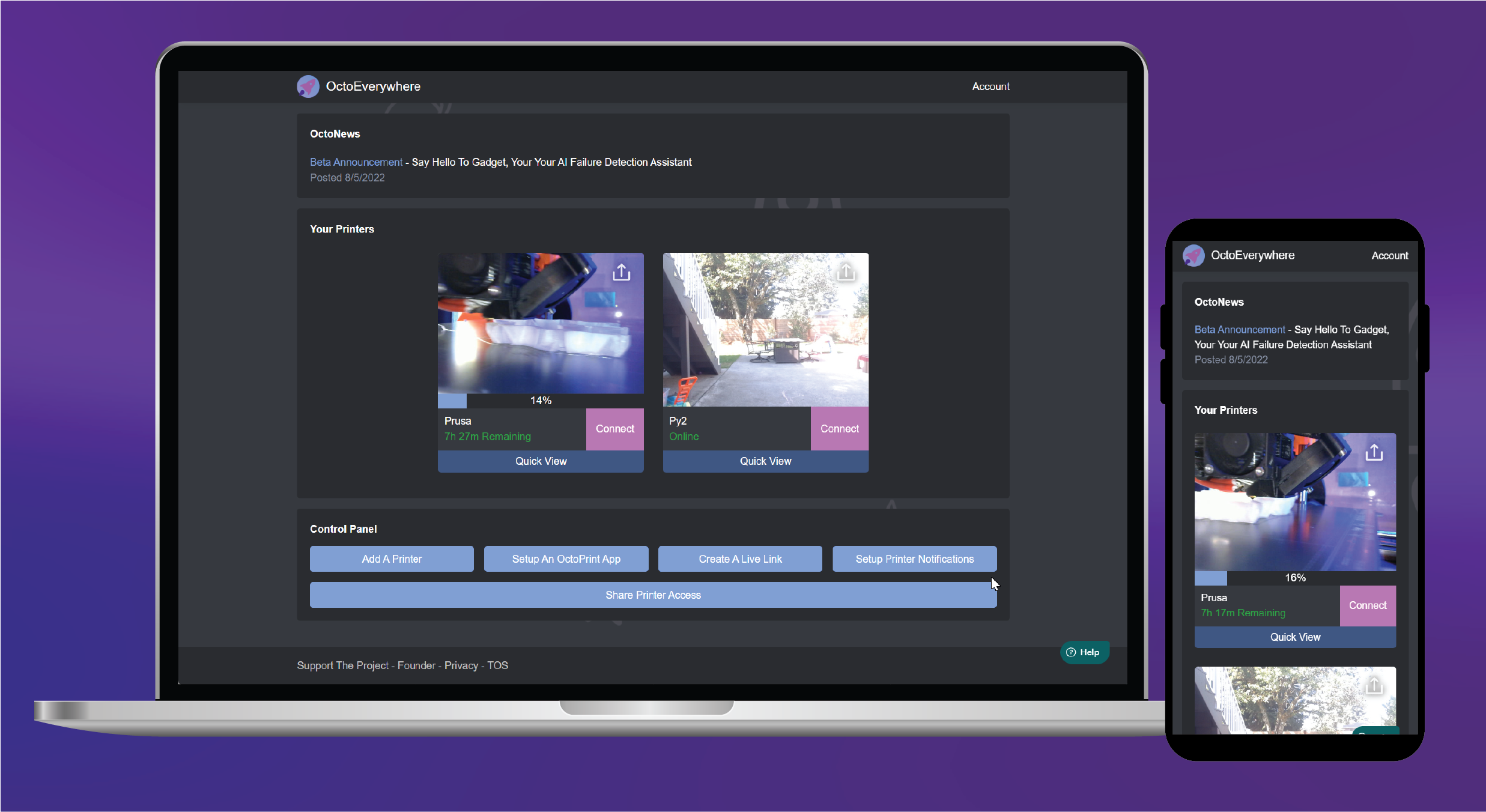

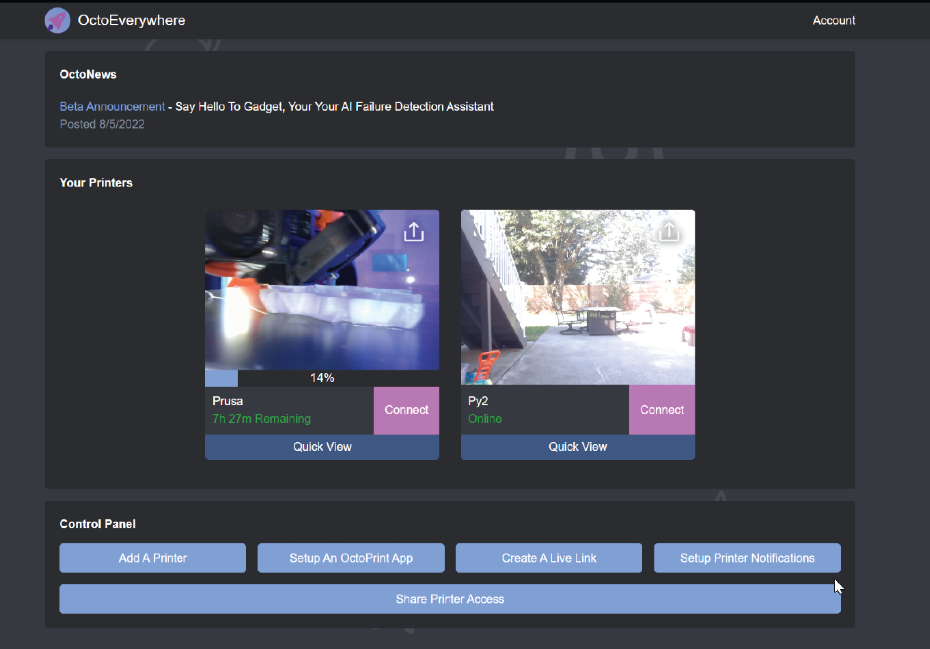

OctoEverywhere is a powerful tool designed to give you complete remote access and control over your 3D printer from anywhere in the world. It comes with AI failure detection features that allow you to pause prints and get alerts when a failure is detected.

source: octoprint.org

source: octoprint.org

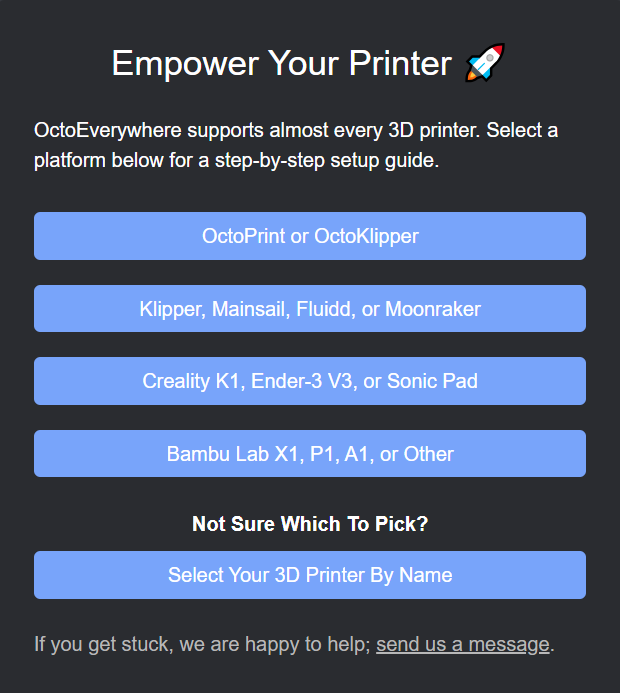

Initially a plugin for OctoPrint, OctoEverywhere now supports more platforms, like Klipper and Bambu Lab printers. It integrates with many 3D printers and platforms, including OctoPrint, OctoKlipper, Klipper (Mainsail, Fluidd, and Moonraker), Creality K1, Ender 3 V3, Sonic Pad, Bambu Lab X1, P1, A1, and more.

However, its user interface lacks some features found in Obico. For example, you cannot upload files to start a print, explore G-codes, view print history or statistics, control bed or nozzle heat, move the print head, extrude filament, or send G-codes through a terminal or console. Instead, it relies on the web interface of the platform it integrates with, like Fluidd for Klipper, as when you click on Connect on the OctoEverywhere user interface, it will direct you to the Fluidd interface to control your printer and firmware configurations (this is, for example, if you are using Klipper with Fluidd and you have installed OctoEverywhere based on that).

source: octoprint.org

source: octoprint.org

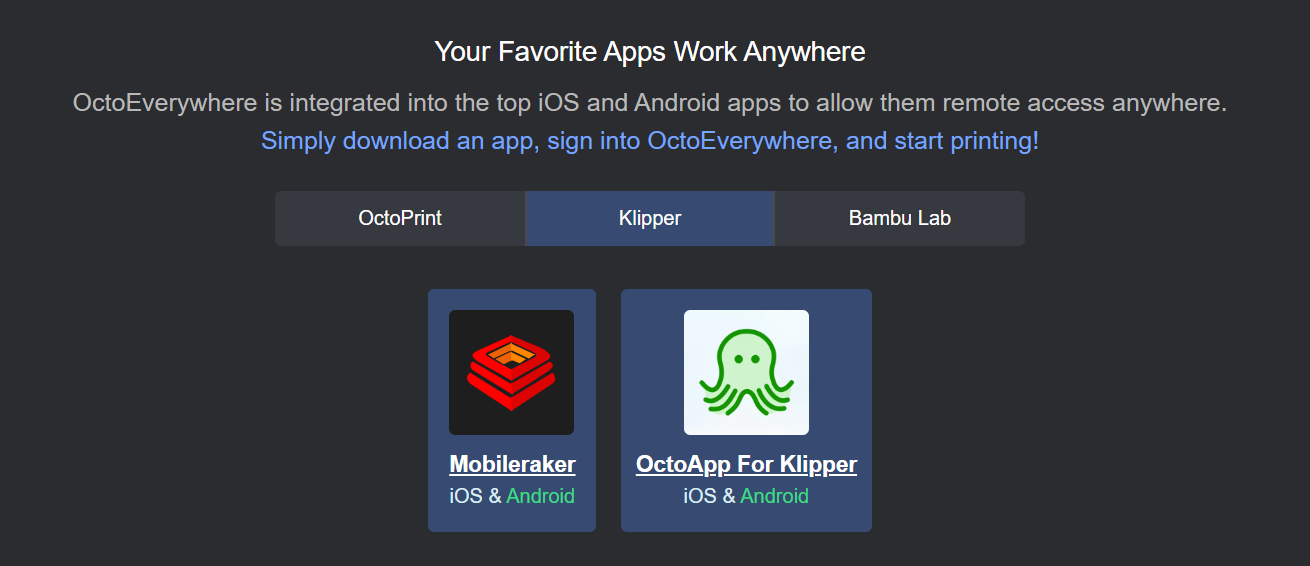

OctoEverywhere's most important feature is its ability to control your printer remotely from anywhere, not just when connected to the same local network. It enhances OctoPrint by providing access beyond the local network, overcoming OctoPrint's limitation to devices on the same network. It integrates with many mobile applications like OctoApp, Printoid, Polymer, Octopod for Octoprint and Mobileraker, and OctoApp for Klipper, giving you the ability to use these apps from anywhere in the world, not only when connected to the local network. They also have their own apps for iOS and Android called OctoEverywhere, through which you can control many printers, like Bambu lab printers. providing easy access from your phone.

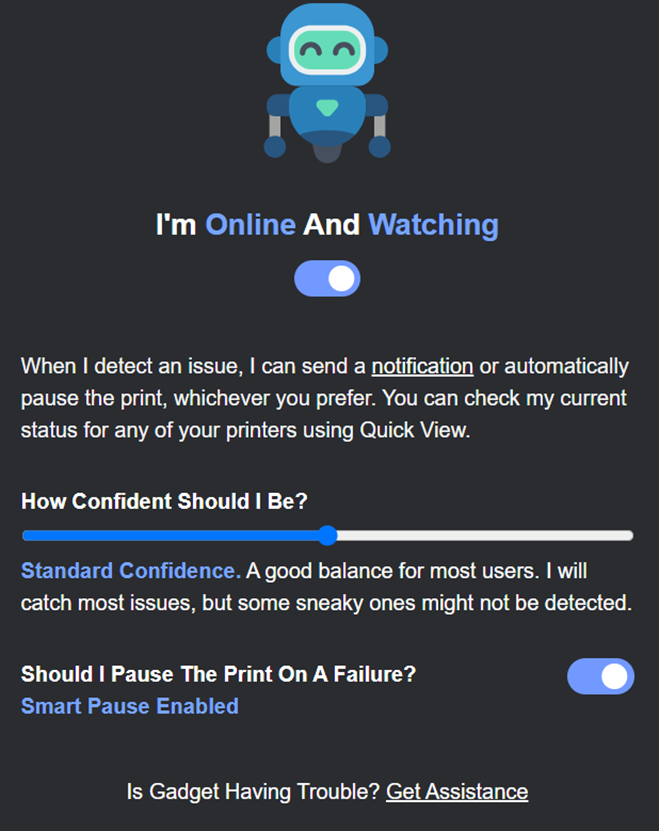

A standout feature of OctoEverywhere is its AI failure detection, known as Gadget. Gadget uses advanced machine learning algorithms to monitor your prints in real time, detecting potential failures during the printing process. When Gadget identifies a problem, it can pause the print and notify you immediately, allowing you to address the issue promptly. You can adjust its sensitivity and decide whether to enable automatic pausing upon failure.

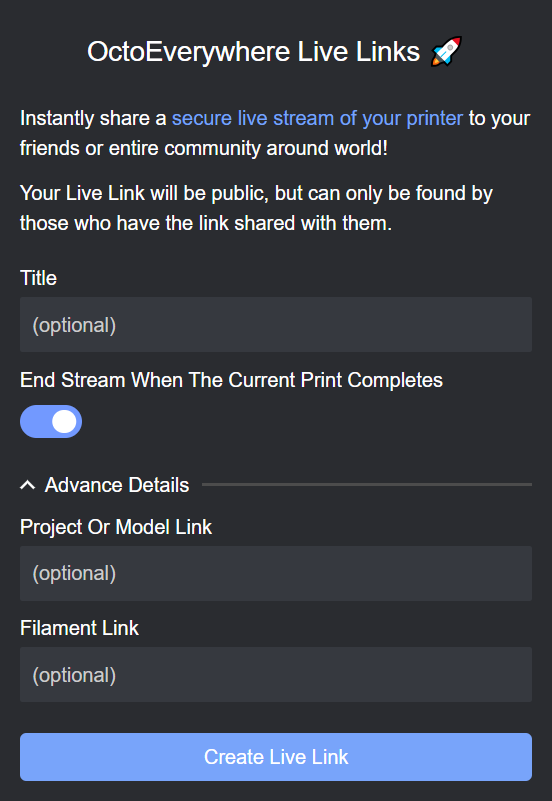

In addition to its robust failure detection capabilities, OctoEverywhere offers features like live links, allowing you to share a live stream of your printing process with friends, family, or social media followers. This is useful for showcasing new designs or demonstrating your printing capabilities.

Another useful feature is the ability to share printer access. This means you can allow others to manage your printer or receive updates about the printing process. This is particularly helpful if you need assistance or if you want to keep multiple people informed about a print's progress. OctoEverywhere also supports the management of multiple printers from one interface, making it a great tool for small-scale 3D printing farms or enthusiasts with more than one machine.

Lastly, the OctoEverywhere website lacks detailed documentation, especially about their AI system. But there is a live chat feature where you can get help and support. Also, they have a Discord community where you can interact with other users. There are also detailed guides for installing OctoEverywhere on your printer with clear and easy-to-follow steps.

FAQs

Introduction

Q1: What is AI error detection in 3D printing?

AI error detection in 3D printing refers to the use of artificial intelligence systems to monitor the printing process in real-time. These systems detect potential failures and anomalies, allowing users to prevent material waste and save time and money.

Q2: How does AI error detection work in 3D printing?

AI error detection works by analyzing data from sensors like cameras or LiDAR during the printing process. Machine learning algorithms compare real-time data with trained datasets to identify patterns and detect potential failures.

Obico AI Detection System

Q3: What is Obico, and what does it offer?

Obico is an open-source and AI-powered platform for 3D printing. It provides comprehensive failure detection, remote monitoring, and control features. Obico integrates with platforms like Klipper and OctoPrint.

Q4: How does Obico's general AI detection system work?

Obico's general AI detection system monitors the entire printed part using a camera. It analyzes images at regular intervals to detect common issues, such as the spaghetti, and can alert users or pause the print if a problem is detected.

Q5: What is Nozzle Ninja, and how does it differ from the general AI detection system?

Nozzle Ninja is a specialized AI system by Obico that focuses on the critical first layer of the print. It uses a dedicated nozzle camera to detect issues like under-extrusion, over-extrusion, bed adhesion problems, warping, bubbling, and nozzle blobbing.

Bambu Lab AI Detection System

Q7: What are the AI-powered features of the Bambu Lab X1-Carbon printer?

The Bambu Lab X1-Carbon features Spaghetti Detection using a USB camera and Micro Lidar technology for precise first-layer inspection. It also has dual auto bed leveling for accurate prints.

Q8: How does Spaghetti Detection work in the Bambu Lab X1-Carbon printer?

Spaghetti Detection uses a camera to capture frames of the print process. The AI analyzes these frames to detect potential "spaghetti" failures and can pause the print to prevent further issues.

Q9: What is Micro Lidar, and how does it enhance printing quality?

Micro Lidar measures depth with micrometer precision, scanning the print bed and the first layer to ensure correct alignment. It adjusts the nozzle height and filament flow, reducing the likelihood of errors from the start.

Creality K1 Max AI Detection System

Q10: What AI features are included in the Creality K1 Max printer?

The Creality K1 Max includes AI LiDAR for first-layer inspection and an AI camera to detect spaghetti failures, foreign objects, and debris. It provides real-time monitoring and time-lapse video creation.

Q11: How does the AI LiDAR work in the Creality K1 Max?

AI LiDAR scans the first layer with high precision. If it detects issues, it pauses the print and notifies the user immediately, ensuring any problems are addressed right away.

Nexus AI for OctoPrint

Q12: What is Nexus AI, and how does it function?

Nexus AI is an open-source plugin for OctoPrint developed by Fiberpunk. It uses machine learning algorithms to detect print failures by analyzing images from OctoPrint-compatible cameras.

Q13: What are the benefits of using Nexus AI?

Nexus AI is easy to deploy and has low hardware requirements. It runs on a local server, ensuring data security, and provides notifications for detected issues. It is also open-source, encouraging broader integration and development.

OctoEverywhere AI Detection System

Q14: What is OctoEverywhere, and what are its key features?

OctoEverywhere is a tool for remote access and control of 3D printers. It supports multiple platforms and offers AI failure detection, known as Gadget, which monitors prints in real-time and alerts users to potential failures.

Q15: How does Gadget work in OctoEverywhere?

Gadget uses machine learning algorithms to analyze the print process. It can pause the print and notify the user when a potential failure is detected. Users can adjust its sensitivity and enable automatic pausing.

Q16: What are some limitations of OctoEverywhere compared to Obico?

OctoEverywhere lacks certain features like file uploads to start a print, G-code exploration, and control of bed or nozzle heat. It relies on the web interface of the platform it integrates with for detailed controls.

Q17: Can OctoEverywhere manage multiple printers?

Yes, OctoEverywhere supports the management of multiple printers from one interface, making it a suitable tool for small-scale 3D printing farms or enthusiasts with several machines.

Q18: Where can I find support and documentation for OctoEverywhere?

While the OctoEverywhere website lacks detailed documentation, it offers a live chat feature and a Discord community for support. There are also guides for installing OctoEverywhere on various printers.

General Questions

Q19: What are the advantages of AI error detection in 3D printing?

AI error detection minimizes material waste, saves time and money, and increases the success rate of 3D printing projects. It allows users to address issues promptly, enhancing the reliability and quality of prints.

Q20: Which AI detection system is the most accurate?

Obico's AI detection system is considered the most accurate due to its extensive dataset and continuous improvement. However, other systems like Bambu Lab, Creality, Nexus AI, and OctoEverywhere also offer reliable detection capabilities tailored to specific needs.

In conclusion, AI error detection in 3D printing is a game-changer that helps catch problems early, saving time, money, and materials. Different systems offer various features to enhance the printing experience. Obico is highly accurate and compatible with many printers, providing comprehensive monitoring from start to finish. Bambu Lab's X1-Carbon uses advanced AI to ensure high-quality prints with features like Spaghetti Detection and Micro Lidar. Creality's K1 Max combines AI LiDAR and an AI camera to watch for issues and notify users immediately. Nexus AI is an open-source option for OctoPrint users, running on a local server for enhanced security. OctoEverywhere offers remote control and AI failure detection, making it easy to manage multiple printers from anywhere.

Each system has its own strengths, so you should choose the one that best suits your needs and is compatible with your setup.