Best CoreXY 3D Printers In 2024

Source: Voron Design

The CoreXY 3D printer space has been getting quite popular in the past few months. With the release of printers like the Bambulab X1 and P1 series and the pre-existing Voron 3D printers, CoreXY 3D printing has become the norm nowadays.

The CoreXY design, with its fast printing speeds, enclosed build area, and compact printer footprint, offers several benefits. What's more, these 3D printers have become much more affordable and accessible, giving you a wide range of choices and empowering you to explore this exciting technology.

In this piece, we have collected a list of the top 5 CoreXY 3D printers you can get for yourself right now. These are all aimed at hobbyists, personal use, small-business owners, and users who are looking to get their first CoreXY machine.

Get ready to dive into the core of 3D printing excellence. Let’s start!

What Is a CoreXY 3D Printer?

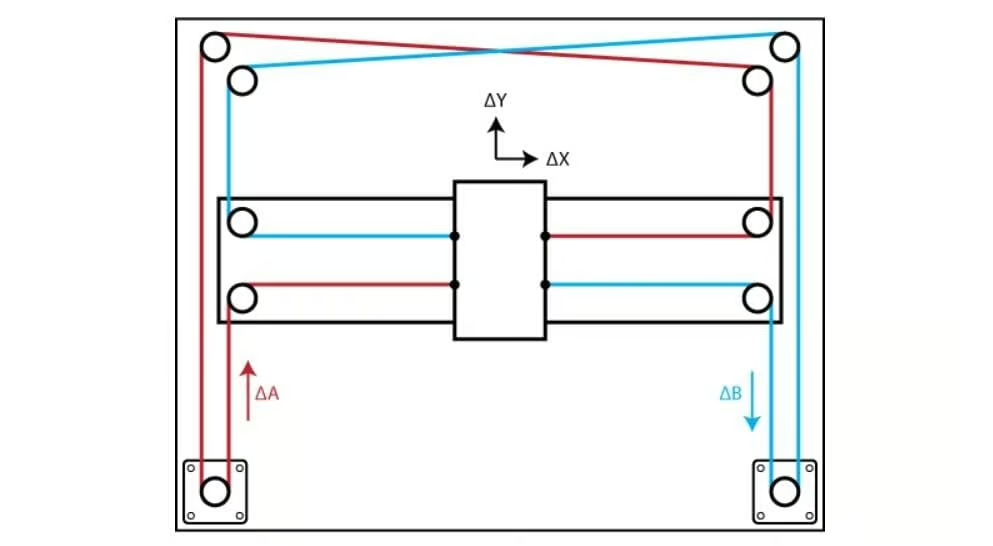

Source: CoreXY

A CoreXY 3D printer uses a distinctive motion system that sets it apart from the Cartesian i3 style and the Delta 3D printers. In a CoreXY setup, the stepper motors are fixed to the frame of the printer, and the print head is moved by a series of belts arranged in a crossed pattern. This belt configuration allows the print head to move simultaneously in the X and Y directions by coordinating the motors’ movements, resulting in a more efficient and precise motion.

The Z-axis, which handles the vertical movement, is typically managed by a separate mechanism, often a lead screw or threaded rod. This separation of the Z-axis from the X and Y-axes reduces the moving mass of the print head, leading to several significant benefits –

High Precision: Due to the fewer moving parts, there’s less inertia, leading to CoreXY printers achieving greater accuracy and finer detail in printed objects.

Speed: The motors only have to move the print head, not the entire printing axis (cartesian XZ arrangement). This allows for high-speed 3D printing without losing out on print quality.

Stability: The print bed in a CoreXY printer is stable and doesn’t move around much. Additionally, the CoreXY design allows for robust frame structure which further increases the overall stability of the printer.

These printers also often feature advanced capabilities like automatic calibration, enclosed build areas for better temperature control, and the ability to print with multiple materials. This makes them versatile for various projects, from prototypes and functional parts to artistic 3D prints.

However, the complexity of the CoreXY mechanism also presents some challenges. These printers are generally more expensive than basic Cartesian models due to their sophisticated design and components. Their maintenance is also more complicated than other styles of 3D printers, and it can be daunting for beginners with no experience in 3D printing.

Despite these drawbacks, the speed, precision, and stability of the CoreXY 3D printers make them a lucrative option for many. Especially with the newer generation of faster, well-built, and professional CoreXY printers, these machines can help you achieve professional 3D prints quite easily.

CoreXY 3D Printers

Best Overall

Bambu Lab X1-Carbon 3D Printer

It’s been two years since the release of the Bambulab X1C and it is still the reigning 3D printer for many users. With a build volume of 256 x 256 x 256 mm, the X1C sits comfortably on a desktop. This print volume allows you to print miniatures, toys, enclosures, home decor items and even small helmets, covering a wide range of 3D printing models.

Bambulab’s proprietary hotend can reach temperatures up to 300°C, with the build plate heating up to 120°C. Furthermore, the print area is enclosed on all sides with glass and aluminum panels. This combination gives you the freedom to print with high-temperature materials like Nylon, Polycarbonate, Polypropylene, and ABS.

The X1C packs in a LIDAR sensor for perfect first layers. There’s a spaghetti detection feature, similar to Obico, which helps to automatically detect print failures. This feature is designed to identify when the printer is producing 'spaghetti' or a tangled mess of filament, and it can pause the print or alert you to prevent wasted time and material.

Another standout feature is its Automatic Material System (AMS). With the AMS, you can easily print multi-color 3D models on the X1C. A single AMS can print in up to four colors, and you can hook up to four AMSs on a single X1C printer, giving you the ability to print with up to 16 colors!

In terms of its shortcomings, swapping nozzles on the X1 can be quite a task. The AMS also generates a lot of filament waste, which in some 3D prints can be more than the weight of the model itself. Lastly, it’s a pretty closed ecosystem, which can be detrimental to hobbyists and tinkerers.

All things considered, the X1C is a complete package for those who like a plug-and-play 3D printer. Its robust design, enclosed print area, and ease of use make it one of the best CoreXY 3D printers available right now.

Features:

- Lidar sensor for bed leveling

- Active vibration compensation

- Spaghetti failure detection

Pros

- Fast printing speeds

- Capable of printing with up to 16 colors

- Easy to use

- Excellent build quality

Cons

- High price

- Proprietary components and software

Best for Hobbyists

Creality K1C

Although marketed as a carbon filament 3D printer, the Creality K1C is more of an upgrade to the original Creality K1. It comes with a better extruder, an upgraded nozzle, an air filter, a camera in the build chamber, and vibration-damping feet.

You get a modest 220 x 220 x 250 mm of build volume with the printer, enough for printing wide variety of 3D models. The entire print area is enclosed with acrylic on all the sides, with a glass door on the front for easy access. Creality has improved the durability of this glass door over the K1 and now the door comes with a anti-shatter film.

Owing to its CoreXY design, sturdy frame, and modified Klipper firmware, the K1C can reach print speeds of up to 600 mm/s with a maximum acceleration of 20,000 mm/s². These speeds allow you to iterate your designs quicker and improve the overall productivity of your projects.

The 300 °C hot end comes with a hardened steel nozzle designed to print abrasive materials like carbon fiber filaments. The higher temperature and enclosed build area also allow you to print ABS, PC, PP, and Nylon, making it an excellent printer for engineering applications.

The filament path, however, on the K1C is still the same as the K1 and remains the achilles heel of the printer. It constricts the filament more than we’d like, and brittle PLA filaments can break easily.

As someone who likes to experiment with 3D printing and print quality parts at high speeds, you will come to like the K1C. It’s priced less than a similarly specced Bambulab printer and offers plenty of features to suit the needs of both hobbyists and professional 3D printer users.

Features:

- Tri-metal nozzle system

- Triple fan cooling design

- One-Tap auto-calibration

Pros:

- 300c high-temperature hot end

- Camera for print monitoring

- Relatively less price

- Excellent printing speeds

Cons:

- The filament path is poorly designed

- Noisy fans

- Inadequate air filter

Best DIY

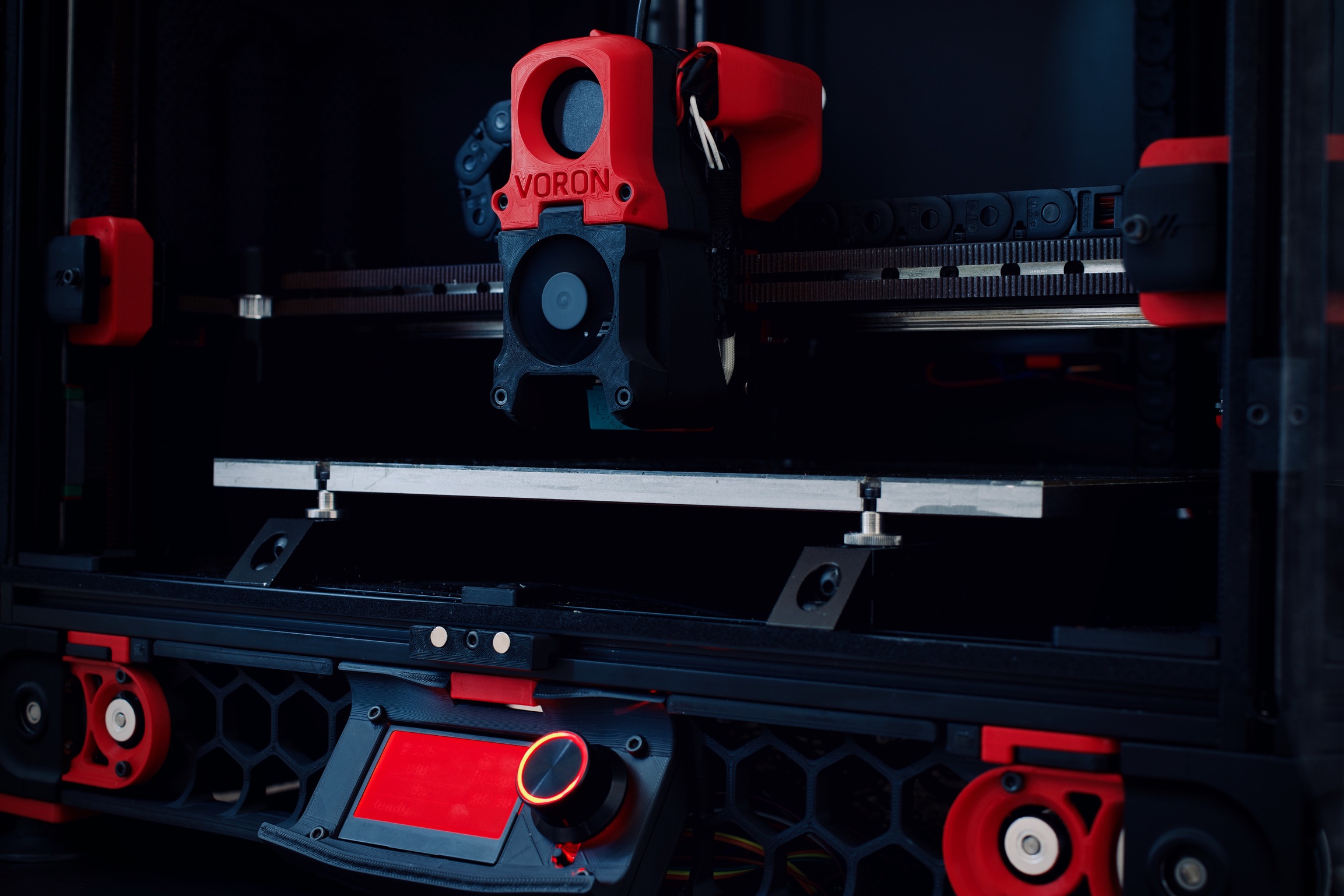

Voron 2.4

The Voron 2.4 printer kit is based on the original Voron project and comes with top-notch 3D printing components. It’s a maker’s 3D printer, and you can customize almost every element of it.

This particular Formbot kit offers all the components of the Voron 2.4 design except the 3D-printed parts. Additionally, this kit includes the Canbus Wiring System, which stands out from almost any other 3D printer in the lineup. With the Canbus system, the print head wiring is greatly optimized, and there’s less mess and weight on the print head, leading to faster and more precise movements.

Regarding its hardware, the Voron 2.4 runs the Bigtreetech’s Manta M8P motherboard at its heart. It’s a 32-bit motherboard with plenty of I/O ports and runs Klipper natively. You get linear rails on the X&Y axes with Gates’ belts for movement on the Z-axis. The kit also has Moons’ stepper motors for higher torque and faster movement speeds.

The all-metal titanium hot end is designed to reach temperatures of 300 °C, and it is coupled with the heated print bed and an enclosed design. With this feature set you can easily print high-temperature materials. If you need, you can upgrade the hot end to a Phatues Dragon hot end for up to 500 °C printing and further extend the material compatibility.

As you have the assemble the printer all by yourself, it’s not recommend for beginners in 3D printing. There’s considerable amount of calibration and fine-tuning of the print settings even after assembly, which can detract from the printing experience. Additionally, the price tag might deter you, if you’re used to plug-n-play 3D printers.

The Voron 2.4 can be a difficult 3D printer to assemble, but it delivers excellent performance once you dial down the settings. The print speeds are incredible, the design and build are excellent, and you can print a wide variety of materials with the correct configuration. It’s one of the best CoreXY 3D printers if you’re an experienced user and like to tinker with your machines.

Features:

- Canbus Wiring System

- Stealthburner + CW2 extrusion system

- Customizable build volume

Pros:

- Fully enclosed print area

- Fast printing speeds

- Consistent and high-quality extrusion

- High-level of customization

Cons:

- Assembly can be tedious

- Needs extensive calibration

- Limited resources and support

Best on a Budget

Kingroon KLP1

Kingroon’s KLP1 breaks the stereotype that good CoreXY printers are expensive. For less than $400, this 3D printer offers all the benefits of the CoreXY design with few to no drawbacks.

The KLP1 is enclosed on all sides, allowing printing with temperature-sensitive materials. The 300 °C, hot end further helps with printing high-temperature filaments, enabling you to print an extensive range of 3D printing materials.

Its 230 x 230 x 210 mm print area, albeit smaller, gives you enough room to print most 3D models. You can easily print small toys, tools, cosplay pieces, and even prototype scaled models.

The linear rails on the X and Y axes are a noteworthy feature, which, coupled with the Klipper firmware, gives you excellent printing speed and precision. With the KLP1, you can print at speeds of up to 500 mm/s while maintaining top-notch print quality.

The KLP1's Fluidd Klipper web interface is a refreshing touch for the printer. You can easily control all the functions wirelessly from your laptop and manage your printer from far away. The onboard touchscreen is decent and runs the intuitive KlipperScreen UI.

While the KLP1 offers excellent price value, it has a few shortcomings. The printer's Z-height is smaller than most CoreXY machines, restricting the maximum size of the model you can print. Moreover, the touchscreen, too, can be more responsive as it sometimes fails to register inputs.

Overall, for $369, the Kingroon KLP1 delivers exceptional print quality and speeds, has wide material compatibility, and packs all the features of the Klipper firmware. It makes great sense for someone on a tight budget who needs a CoreXY printer that simply works.

Features:

- Klipper Firmware

- All-metal extruder

- 300 °C all metal hot end

Pros:

- Linear rails on the X and Y axes

- 36-point fast bed leveling

- Rapid heating times

- Affordable price

Cons:

- Smaller print area

- The touchscreen can be unresponsive

Best Enclosed CoreXY

Qidi Tech X-Plus 3

Not all enclosed 3D printers are created equal, and the QIDI Tech X-Plus 3 proves this point well. It features some of the best features amongst CoreXY 3D printers and makes for an excellent engineering grade machine.

To start, the enclosed print area is actively heated with a separate heating element. The build chamber can reach and sustain temperatures of up to 65 °C in under 8 minutes. This helps with warping and layer delamination issues with temperature-sensitive materials. The ABS, Nylon, and Polycarbonate prints come out great with fewer quality issues.

QIDI Tech ships the X-Plus 3 with two high-temperature hot ends. These hot ends can reach temperatures of up to 350 °C, and their heating times are impressive. One hot end comes with a conductive copper alloy nozzle for your typical 3D printing filaments. At the same time, the second one comes with a hardened steel nozzle for abrasive filaments.

In terms of build quality, the X-Plus 3 is built like a tank. The all-metal frame stabilizes the printer as it prints at speeds of over 500 mm/s. The carbon fiber rods on the XY axes are stiffer and lightweight than steel, allowing for faster and more precise printing performance. The enclosure quality is robust, too, further increasing the printer's durability.

The inbuilt filament dryer is a neat little addition as well. It helps to keep the filament dry, which is useful when printing with hygroscopic materials like Nylon and PETG. However, the dry box is a bit hard to access. The lack of an air filter is apparent, too, and should’ve been included with the printer.

For $569.00, you get a heated build chamber coupled with a 350 °C hot end. If you want to print engineering prototypes and even functional 3D models, the QIDI Tech X-Plus 3 can be an excellent machine for your workshops and engineering businesses.

Features:

- Actively heated build chamber

- Dual high-temperature hot ends

- Built-in filament dryer

Pros:

- Large build volume

- Extensive filament compatibility

- Stock Klipper firmware

- Fast heating speeds

Cons:

- Lacks air filter

- Noisy at high-print speeds

Should You Buy a CoreXY 3D Printer Now?

Yes, buying a CoreXY 3D printer makes sense now more than ever. The capabilities of these machines have improved significantly over the past couple of years. The value proposition of these printers is excellent, and they’re no longer limited to solely professional users.

The likes of Bambulab X1C and Creality K1C simplify the usability of CoreXY 3D printers. You also have the budget Kingroon KLP1 3D printer, which makes the benefits of the CoreXY mechanism more affordable and accessible than before.

So, Yes! If you want the benefits of fast printing speeds, top-notch print quality, and an enclosed print volume, you should consider getting a CoreXY 3D printer.

Which CoreXY 3D Printer Is the Best for Me?

The more choices you have, the more confusing it gets to choose a 3D printer that best suits your needs. Before finalizing the printer that’s best for you, you need to consider the purpose and your preferences.

In this section, we’ll briefly discuss the points that will help you choose a printer that perfectly matches your preferences.

3D Printing Experience

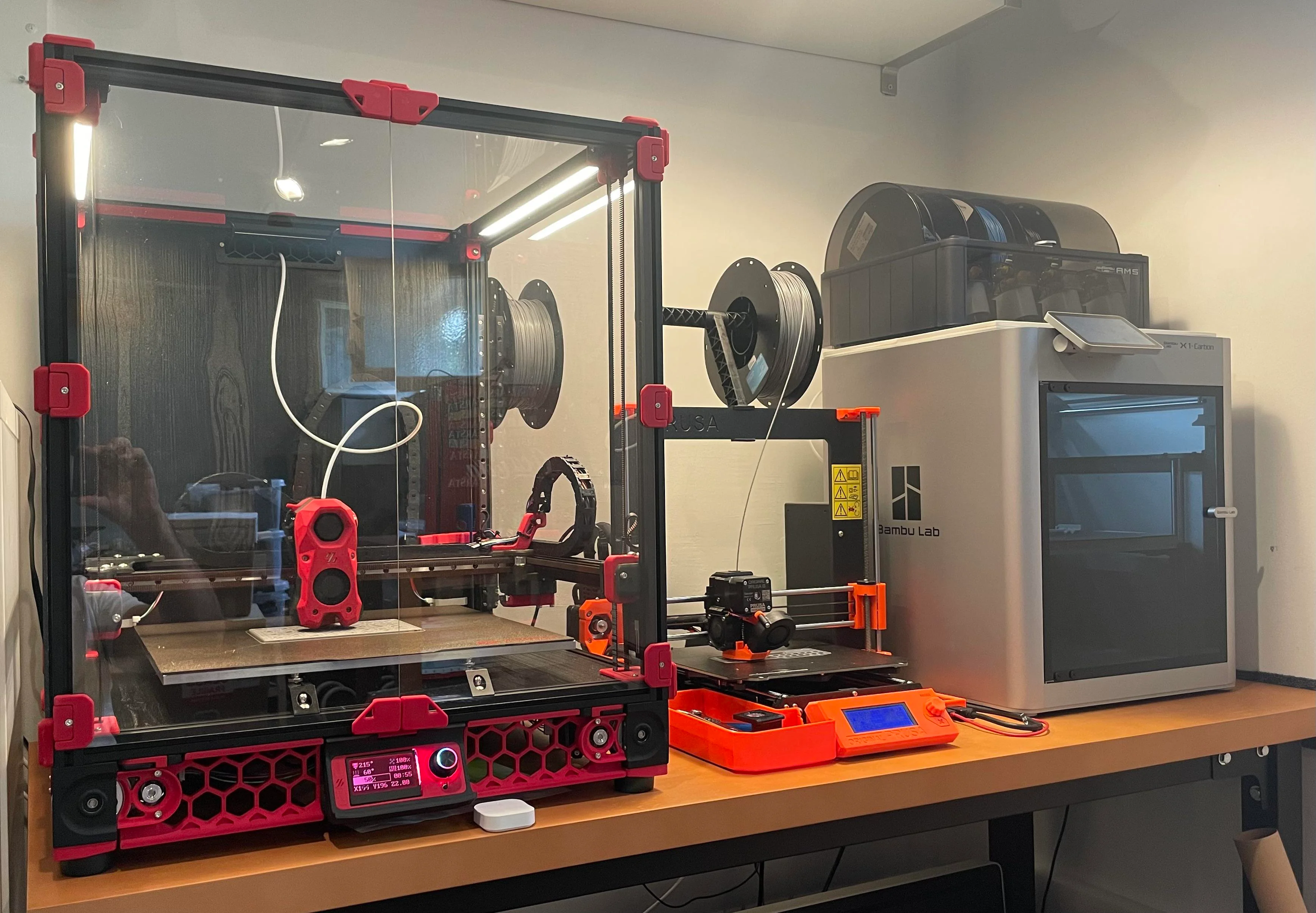

Source: guzzlovic via Reddit

A CoreXY 3D printer can be slightly more complex than your average Prusa-style machine. Before finalizing a 3D printer, it definitely helps to know the level of your 3D printing experience.

For instance, if you’re a novice to 3D printing, getting a Voron 3D printer doesn’t make much sense. You have to build it entirely from scratch, calibrate it, and fine-tune the printing parameters. This process can be daunting for beginners and discourages you from even getting into 3D printing.

The Bambulab X1C is better suited for those new to 3D printing. It offers a much more streamlined workflow, and the closed ecosystem helps with the user experience. The printer comes completely assembled out of the box, and you can begin printing in a couple of hours. There’s little to no calibration, and you can enjoy the printing process itself.

If you have budget issues, you can try getting the Kingroon KLP1 as an alternative. It can be an excellent introduction to CoreXY 3D printing at almost half the price of the X1C. The print quality is relatively good, and you still get the benefits of fast 3D printing.

Model Size

Source: Boespflug via Thingiverse

Are you going to print swords, large cosplay helmets, or small electronic enclosures? What’s the average build size for your 3D prints? You need to have a rough idea of these questions before finalizing a CoreXY 3D printer.

The Bambulab X1C and the Creality K1C 3D printers give you a build area of roughly 250 x 250 x 250 mm. This print size is the average for most 3D printers and gives you a good area for printing medium-sized 3D prints. You can comfortably print small toys, batches of miniatures, lithophanes, and small home decor items.

The Voron kit allows you to customize the build size to up to 350 x 350 x 350 mm. This print area is suited for large cosplay prints, helmets, tall vases, and even big enclosures. However, due to the large print area, you need to consider the increased footprint and price.

In contrast, if your printing purpose is small models, toys, desk organizers, and occasional vases, Kingroon’s KLP1 is apt for your needs. It has a short height of 210 mm, but the lower price is more attractive for hobbyists and users on a budget.

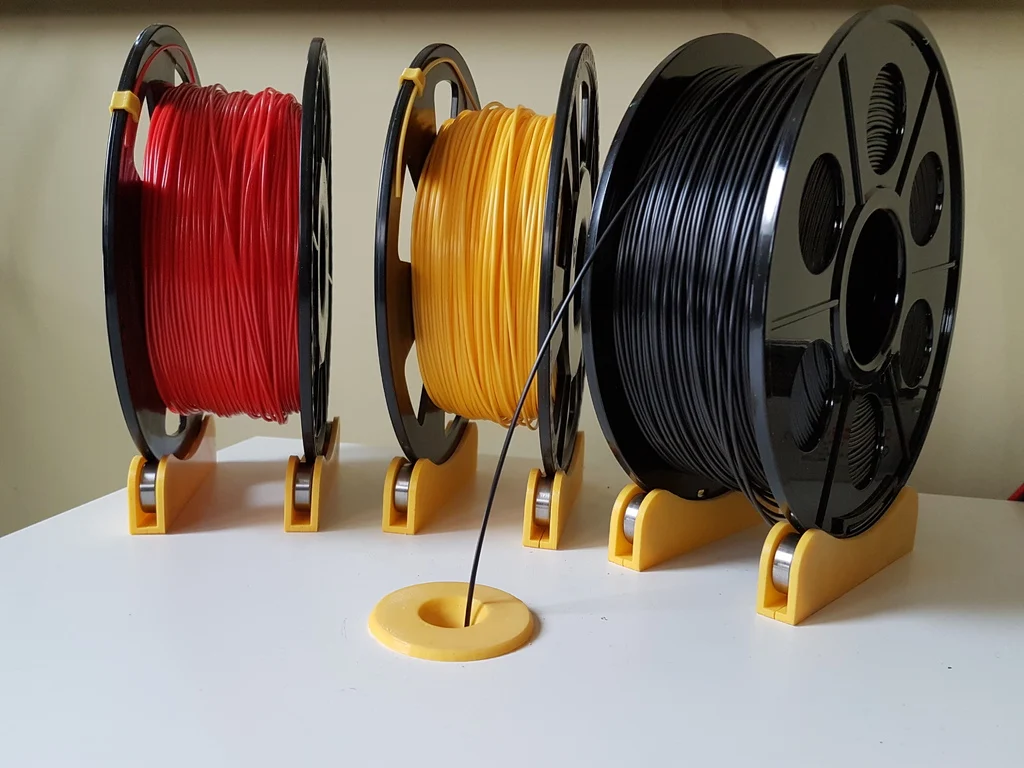

Material Needs

Source: filamentry via Thingiverse

The enclosed print area of a CoreXY machine gives you the ease of printing with an extensive range of filaments. In addition to the usual PLA, PETG, and TPU, you can easily print temperature-sensitive materials like ABS and Nylon on these machines.

If you’re into engineering applications and 3D print prototypes for a living, the QIDI Tech X-Plus 3 offers the best filament compatibility. Its heated build chamber, dual sets of hot ends, and a 350 °C nozzle temperature all work in your favor. You can print with engineering-grade materials like Polypropylene, Nylon, Polycarbonate, and Carbon fiber without worrying about their downsides.

With the Voron 2.4, you can upgrade the kit to fit a Phaetus Dragon hot end and print at temperatures up to 500 °C. It further extends the range of filaments, allowing you to print exotic plastics like ULTEM and PEEK, typically reserved for high-end 3D printers.

The rest of the CoreXY 3D printers are all rated similarly in terms of filament compatibility. Every 3D printer reaches up to 300 °C, and you can comfortably print ABS and other high-temperature filaments.

The Bambulab X1C, however, offers a unique advantage with its AMS feature. It’s the only printer in this lineup that you can use for multi-color and multi-material 3D prints. If you need multi-color 3D prints, this is your best option.

Price

The Kingroon KLP1 3D printer is an excellent option for budget users at ~$350. It comes with the Klipper firmware, 500 mm/s print speeds, a high-temperature hot end, and all the benefits of a CoreXY design. However, for the lower price, you need to give up on the print area and a better build quality.

In the mid-segment, Creality’s K1C and the QIDI Tech X-Plus 3 are excellent CoreXY 3D printers at ~$500. These machines offer better features than the KLP1 and a better user experience.

Lastly, if you have the budget and want a genuinely plug-and-play Core XY 3D printer, the Bambulab X1C is the best option. Its ~$1000 price tag is almost double that of the alternatives, but you get the best user experience of all the machines. The build quality is excellent, as are the printing results. You can print with up to 16 colors using the AMS, and the Bambu Studio slicer pairs seamlessly with the printer.

Obico for CoreXY 3D Printers

Obico is one of the few software programs that allows you to experience proper remote 3D printing. With Obico, you can be anywhere in the world and still get a live feed of your 3D printer. It lets you access, control, and manage your 3D printers regardless of your location.

Obico is also trained on millions of hours of print failure data. It uses machine learning and AI to detect print failure and inform you instantly. You can configure Obico to stop the print automatically or notify you, leaving the end action in your hands.

This print failure detection feature can help you save considerable print time and material wastage. These savings will improve your overall productivity and cut down on wasted print times and material costs.

You can easily configure Obico to run on any Klipper 3D printer. It supports the Creality K1C, Voron 2.4, Kingroon KLP1, and even the QIDI Tech X series 3D printers. There’s also a dedicated BTT motherboard that comes with Obico pre-installed, which eases the initial configuration process.

Lastly, if you want complete control over your 3D printing workflow, you can also run your own Obico server. This lets you customize Obico to your work needs and gives you more control over it. There’s also the Obico Discord forum that can help you with any queries and provide support.

Try out Obico for free right now!