Best Upgrades for Bambu Lab 3D Printers

Introduction

If you have a Bambu Lab 3D printer, you’ve already opened the door to a world of creativity, precision, and innovation. Bambu Lab printers are known for being reliable and high quality, so they’re a favorite among users all around the world.

But even great printers can be made better with a bit of customization. With the right printable accessories, you can make your Bambu Lab printer even more efficient, more versatile, and more fun to use. In this guide, we’ll take a look at some of the best 3D printable accessories to get the most out of your Bambu Lab 3D printer.

Whether you want to reduce vibrations, manage your filament better, or tweak your AMS system, these upgrades offer practical and easy-to-print solutions that you can print directly with your Bambu Lab printer.

Let’s get started and see how these upgrades can improve your 3D printing experience.

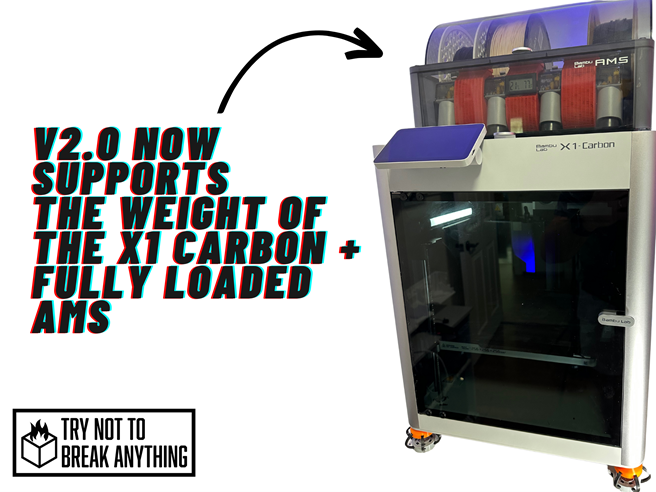

1. TNTBA Anti-Vibration Feet 2.0 for Bambu Lab X1 Carbon + AMS, P1P & P1S

Vibrations are one of the most common issues in 3D printing and can affect print quality, especially during longer or high-speed prints. The TNTBA Anti-Vibration Feet 2.0 is an effective solution to this problem by providing a sturdier base for your Bambu Lab printer. This upgraded version is designed to handle the extra weight of a fully loaded AMS with X1 Carbon printer and provides better vibration dampening than the original feet.

source: cults3d.com

With reduced vibrations, you can expect better print accuracy, less noise, and a more stable printing environment.

- Stronger structure to support a fully loaded AMS on Bambu Lab X1 Carbon.

- Better vibration dampening for harder vibrations for a quieter print environment.

- Almost as good as Bambu Lab stock feet in controlling softer vibrations but better in reducing stronger vibrations.

- Printed with TPU for flexibility and PETG for strength for a perfect balance of stability and vibration absorption.

- Compatible with X1 Carbon, P1P, and P1S 3D printers.

3D printing settings:

- Nozzle: 0.4mm.

- Material: TPU for top and bottom (95A hardness), PETG for clips.

- Infill: 15% with 3 walls, 3 top and bottom layers.

For more details about this anti-vibration upgrade and to print it, visit TNTBA Anti-Vibration Feet 2.0 for Bambu Lab.

2. Bambu Lab Poop Bucket, Filament Waste Bin for X1 and X1 Carbon

During 3D printing, especially when switching between different materials or colors in multi-material printing, the printer needs to purge old filament from the nozzle before it starts using the new material. This purging process is crucial to avoid contamination and get clean and accurate prints. But the purged filament adds up fast and can be a mess around your workspace if not managed properly.

source: cults3d.com

The Bambu Lab Poop Bucket is designed to catch all that waste material in one place. Instead of filament scraps all over your workspace, the Poop Bucket catches everything in one bucket, keeping your area tidy and clean. It comes in different versions so you can choose the one that fits your setup.

- Comes in multiple versions to suit your setup.

- Keeps filament scraps from spreading all over your workspace by containing them in one bin.

- Larger sizes need less frequent emptying, you do not have to empty it too often.

- Easy to print with a simple design that requires no support, so installation is quick and painless.

3D Printing Settings:

- Layer Height: 0.2mm

- Infill: 30% Gyroid

- Material: Ziro Silk PLA and Anycubic Matte Black PLA

- Speed: Standard

- Nozzle Temperature: 240°C

- 3 Walls

- No Raft

- No Support

To get more information and print this waste bin, visit Bambu Lab Filament Waste Bin (Poop Bucket).

3. AMS Stand with Pull-Out

The Automatic Material System (AMS) lets you load multiple materials or colors into your 3D printer and do advanced multi-material or color printing. You can connect up to 4 AMS units together and use up to 16 different filaments in one print job. While this is super powerful, managing multiple AMS units can get messy, especially when it comes to keeping your workspace tidy and functional.

source: cults3d.com

The AMS Stand with Pull-Out mechanism helps you to manage the AMS units efficiently. It holds up to 2 AMS units and keeps them easy to access and stable.

- No visible screw holes on the outside.

- Holds 2 AMS units, with stability and easy access.

- Pull-out mechanism for easy installation.

- The pro model can be upgraded to add as many AMSs as you need.

- Ideal for those using the AMS to connect multiple units and use 16 different filaments at once.

- There is a 3MF file available with pre-configured printing settings.

3D Printing Settings:

- The small locking spring must be printed in PETG.

- No supports for screws or screw holes.

For more details and printing instructions, visit AMS Stand with Pull-Out Drawer for Bambu Lab AMS Units.

4. Hydra PRO – Advanced Bambu Lab AMS

The Hydra PRO is an upgraded multi-material system from the stock AMS for advanced users of Bambu Lab 3D printers. It allows for seamless multi-filament printing and supports wider spools for a more reliable and customizable multi-material experience. Hydra PRO is perfect for advanced users who want more flexibility and stability during multi-filament prints.

source: printables.com

- Supports spool widths up to 79 mm and diameters up to 205 mm, fitting almost all 1 kg spools, even with the lid closed.

- Features a perfect track width for both rear and front rollers, leaving no space for spools to jam.

- Adjustable spool rollers with 9 positions, accommodating spool diameters from 120 mm to 205 mm.

- AMS feeder is angled five degrees backward (same as Hydra AMS) to enable printing with full spools.

- Can be printed in various materials such as PETG, ASA, PLA+, and ABS+.

3D Printing Settings:

- 3 walls, 15% gyroid infill, and a 10mm outer brim for Main pieces.

- Supports built-in for main parts; no external supports needed.

- Rear Rollers with guides: 6 walls (100% infill), classic wall generator, 10 mm brim.

- Middle bar, front roller tool, and optional alignment tool: Classic wall generator, 3 walls, 15% gyroid infill, 10 mm brim.

- Recommended to print with PETG or heat-resistant materials if placed on the printer.

Hydra PRO is more advanced than the standard AMS and requires careful assembly. It is recommended for users with prior experience in mods and multi-material systems. Modifying parts like the front rollers may void the AMS warranty, so new rollers are recommended for those wanting to keep original components intact.

For more information on this spool-handling upgrade and to print it, visit Hydra PRO - Advanced Bambu Lab AMS.

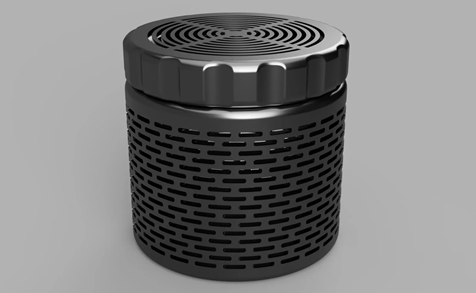

5. Silica Gel Spool Container

Moisture can damage your filament over time and cause stringing, layer separation, and poor adhesion during prints. The Silica Gel Spool Container is an easy-to-print solution that absorbs moisture with silica gel.

source: printables.com

By keeping your filament dry, you get more reliable and better prints, especially in humid environments.

- Designed for fast printing.

- Keeps your filament dry by absorbing moisture so your filament stays good and lasts longer.

- Custom threads designed for FDM printing.

3D Printing Settings:

- Layer height: 0.3mm for fast printing.

- No support required, making it an easy and efficient print.

- Material: PLA or PETG, depending on your preference for durability.

To learn more and print this filament storage container, visit Silica Gel Spool Container for Bambu Lab Printers.

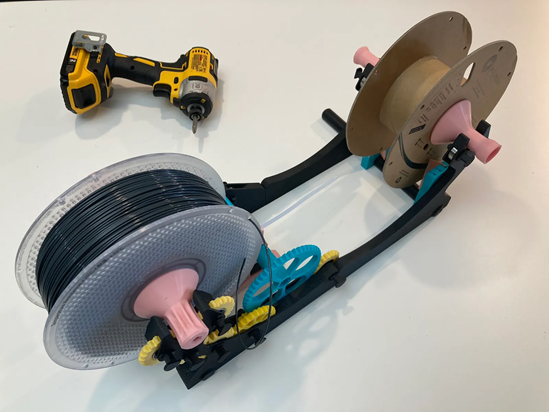

6. Pastamatic Filament Spool Winder for Bambu Lab X1C/P1P AMS

Winding filament is a pain. The Pastamatic Filament Spool Winder makes it easy with its industrial-style self-reversing leadscrew mechanism. This tough and efficient winder winds filament evenly and smoothly, with no tangling and no filament damage. You can print it on one build plate and it requires simple assembly. It is easy to use a must-have for anyone that winds filament spools frequently.

source: printables.com

- Self-reversing leadscrew mechanism for smooth and even winding, no tangling, and no overlap.

- Prints on one build plate, so it’s quick and easy to print and assemble.

- No heat-set inserts or complicated hardware.

- Built to be tough and rugged, it can handle frequent use with minimal wear and tear.

3D Printing Settings:

- Material: PLA or PETG for durability.

- Infill: 5% adaptive cubic infill for lightweight but strong parts.

- Use concentric infill for spindle male-driven part.

For more details and the print files, visit Pastamatic Filament Spool Winder for Bambu Lab.

7. Bambu Lab Y-Splitter with Pneumatic Connectors and Magnets

Switching between filament sources, like the AMS and external spools, can sometimes be tricky. Bambu Lab Y-Splitter with Pneumatic Connectors and Magnets makes this process easier by allowing you to switch between filaments without detaching the AMS. The splitter guides the filament along a natural path, reduces the chance of jams and snags, and sticks to the machine body with magnets for stability and ease of use.

source: printables.com

This is suitable for you if you have spools in a dry box or materials that don’t work well with the AMS, like flexible filaments, and you do not want to detach the AMS too.

- Switch between AMS and external spools without detaching the AMS.

- Pneumatic connectors for a secure fit, no slipping or misalignment.

- Magnets for easy attachment and detach.

- Follows the natural path of the filament, reduces stress on the filament, and smooths feeding.

- It has multiple versions to suit different magnet sizes.

- Relieve the strain on the toolhead PTFE Tube.

3D Printing Settings:

- Material: PETG (optimal) or PLA (best).

- Layer height: 0.08mm (optimal) or 0.12mm (best).

- Walls: 4 (highly recommended).

- Infill: 25%.

- Infill pattern: Grid.

- Enable support: Yes.

- Support type: Tree (auto).

- Support Top Z distance: 0.45mm (for easy removal).

- Support/object XY distance: 0.5mm (to allow easy removal).

- Brim type: Auto (highly recommended for better bed adhesion).

You need to adjust the PTFE tube 22mm to fit inside the Y-Splitter or buy a longer PTFE tube with 2.5mm ID and 4mm OD. Be careful of the toolhead range and make sure the PTFE tube follows a smooth path without any restrictions.

Don’t use abrasive filament materials like carbon fiber polymers to print this splitter, as the rough surface may cause the filament to get stuck inside.

To get more details and print the Y-Splitter, visit Bambu Lab Y-Splitter with Pneumatic Connectors.

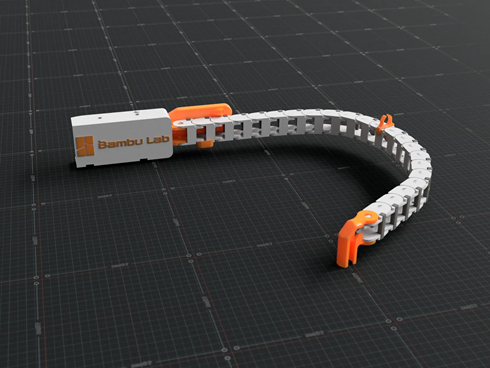

8. Bambu Lab P1P Cable Drag Chain Assembly

Cable management is key to your 3D printer’s performance and longevity. The Bambu Lab P1P Cable Drag Chain Assembly organizes and secures the USB cable and PTFE tube of the P1P printer so it doesn’t tangle and moves smoothly during prints. This is super helpful, as the chain keeps the USB cable and PTFE tube completely inside the P1P, so you can use a cover like the glass lid on the X1 Carbon 3D printer.

source: printables.com

By keeping cables tidy and out of the way, this assembly not only enhances the appearance but also protects the cables from wear and tear, helping them last longer.

- Organizes cables and PTFE tubes so they don’t tangle or obstruct during prints.

- Slightly inclined to prevent sagging, so cables are aligned and secured.

- Reduces wear and tear on cables by protecting them from damage, extending their life and performance.

- Suitable for enclosed or covered top setups, because it keeps the USB cable and PTFE tube completely inside the printer.

3D Printing Settings:

- Material: PETG, PLA+, or ASA.

- Use the same settings in the build plate 3MF file.

Don’t use standard PLA; it will break; PETG, PLA+, or ASA is recommended.

To find out more and print this cable drag chain assembly, visit Bambu Lab P1P Cable Drag Chain Assembly.

9. Bambu Lab A1 Purge Box

The Bambu Lab A1 Purge Box is like the Bambu Lab Poop Bucket but for the Bambu Lab A1. Managing purge waste is a pain, especially when filament bits go everywhere in your workspace.

source: cults3d.com

This purge box is a simple solution to contain all purge material in one place, so you can dispose of waste and keep your workspace tidy. Easy to print and install, it fits in your printer, provides a designated area for purge material, and reduces the need for constant cleaning.

- Collects purge material during prints, so filament doesn’t spread all over your workspace.

- Simple design that fits in your printer setup, easy to install and maintain.

- Reduces the need for constant cleaning by containing waste in one easy-to-remove box.

- Quick and easy to empty when the box is full.

3D Printing Settings:

- Layer height: 0.2mm for fast print.

- Material: PLA or PETG for rigidity and ease of print.

- Bambu Lab Studio setting: X-Y hole compensation: 0.1mm.

To learn more and print this purge box, visit Bambu Lab A1 Purge Box.

10. Bambu Lab X1C Plate Holder

If you use multiple build plates, keeping them organized and secure can be a real pain. The Bambu Lab X1C Plate Holder is the solution—a place to store your build plates safely.

source: printables.com

By keeping your plates organized and protected, you’ll avoid damage or bending, and they’ll be ready for your next print. This easy-to-print accessory is a great way to add functionality to your setup and keep your workspace tidy.

- Stores multiple build plates safely and securely.

- Holds up to 3 build plates.

- Prevents scratches, warping, or damage by keeping plates neatly stored and protected.

- Easy and quick to print.

3D Printing Settings:

- Material: PETG for durability and flexibility.

- Use15% infill to save material and brim for better adhesion.

- No supports needed, making it a fast and easy print.

To learn more and print this build plate holder, visit Bambu Lab X1C Build Plate Holder.

Additional Resources

For more ways to upgrade and customize your Bambu Lab 3D printing experience, check out:

-

MediaMan3D’s Collection of Bambu Lab Upgrades & Accessories

This collection in Printables has upgrades for X1C, P1P, P1S, and AMS systems and lots of creative and practical solutions for your setup.

-

Best 3D Printable Accessories for BambuLab Printers

A curated selection in cluts3d of useful and cool 3D printable accessories to help you get the most out of your Bambu Lab.

Both of these collections have great ideas to fine-tune your Bambu Lab printer to make your 3D printing life easier.

FAQs

-

Q: What materials should I use to print these accessories?

Answer: Most accessories are best printed with PETG, PLA+, or ASA for strength and durability. Avoid using standard PLA for parts that need high flexibility or heat resistance, as it will break.

-

Q: How do anti-vibration feet help with printing?

Answer: Anti-vibration feet provide a stable base for your printer, reducing vibrations that can affect print quality. They ensure smoother and more accurate prints, especially during long or high-speed prints.

-

Q: What is the Bambu Lab Poop Bucket, and why do I need it?

Answer: The Poop Bucket collects purged filament waste during prints, keeps your workspace tidy, and prevents filament scraps from spreading. It’s a simple and effective way to manage waste.

-

Q: What does the Y-Splitter with Pneumatic Connectors do?

Answer: The Y-Splitter allows you to switch between AMS and external filament spools without detaching the AMS. It ensures smooth filament transitions and prevents jams or snags.

-

Q: How does the cable drag chain assembly help?

Answer: The Cable Drag Chain Assembly keeps the USB cable and PTFE tube organized, prevents tangles, and protects them from wear. It ensures smooth movement during printing and is ideal for covered setups.

-

Q: What’s the purpose of the Bambu Lab A1 Purge Box?

Answer: The Purge Box contains all purge material during prints and prevents filament waste from spreading across your workspace. It’s a simple way to keep your area clean and manage waste.

-

Q: Do I need special tools to assemble these upgrades?

Answer: No, most upgrades require minimal assembly and no special tools. The accessories are designed to be easy to print and install directly on your Bambu Lab printer.

Final Thoughts

Printing accessories for your Bambu Lab 3D printer can solve common problems like managing filament waste, reducing vibrations, and keeping cables organized. These accessories are easy to print and install and will improve your printing experience.

Each upgrade is focused on a specific function, such as the Purge Box for collecting filament waste or the Cable Drag Chain Assembly to keep cables tidy and moving smoothly. These additions help keep your workspace cleaner and protect your printer’s components.

Explore these upgrades and see how they can boost the performance and lifespan of your Bambu Lab printer.

Happy printing!