Introduction

Hey there! Welcome to the world of 3D printing, a fascinating realm where your ideas can literally take shape before your eyes. At the heart of this exciting world are Fused Deposition Modeling (FDM) 3D printers. Imagine a hot glue gun crossed with a computer-controlled robot – that's kind of what these printers are like. They melt plastic, then precisely lay it down layer by layer to create an object. It's like magic, but it's science!

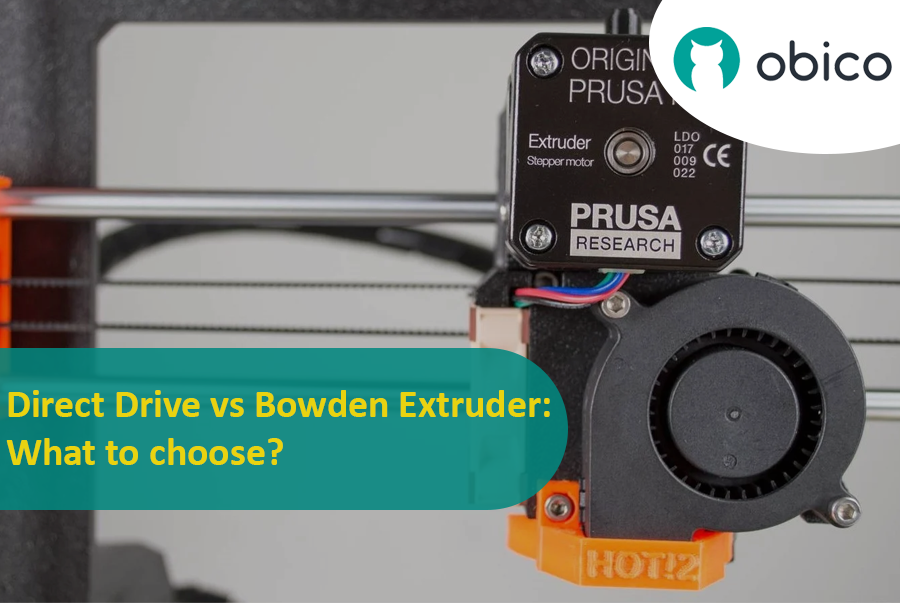

Now, let's talk about a crucial part of these printers: the extruders. Think of an extruder as the 'hand' of the printer that does the actual work of laying down the melted filament. It's a key player because how well your 3D printer can extrude filament determines the quality of your print. Good extrusion means smooth, detailed prints; poor extrusion can lead to a whole host of problems.

There are two main types of extruders you'll hear about: Direct Drive and Bowden. Each has its own set of fans and its own unique strengths and weaknesses. In this guide, we'll dive into the world of these extruders, compare them side by side, and help you figure out which one might be the best fit for your 3D printing adventures. So, let's get started!