How to Print in Wood Filament: Tips and Tricks

Introduction

Welcome to the fascinating world of 3D printing with wood filament! If you're as intrigued as I am about merging the timeless beauty of wood with the cutting-edge technology of 3D printing, then you're in for a treat. Let's dive into what wood filament really is and how it has evolved over the years, transforming the way we think about creating wooden objects.

Brief Overview of Wood Filament in 3D Printing

Picture this: you're combining the natural elegance of wood with the flexibility and precision of 3D printing. That's exactly what wood filament brings to the table. It's a special kind of material that blends tiny wood particles with a polymer base, usually PLA (Polylactic Acid). This concoction allows us to 3D print objects that not only look and feel like they're made of wood but also carry that delightful woody aroma. Whether it's for artistic projects, home decor, or practical applications, wood filament opens up a realm of possibilities, adding a touch of organic charm to our creations.

Historical Development and Innovations in Wood Filaments

The journey of wood filament in the world of 3D printing is quite a story. It all started around 2012 when inventive minds began to explore how they could incorporate natural elements into 3D printing materials. Enter the wood filament, a brainchild that revolutionized the perception of 3D printing. Initially, the early wood filaments had more of a cardboard-like appearance and feel, but oh, how far we've come since then!

Today's wood filaments are much more sophisticated. They're not just about mimicking the look of wood; they're about replicating its very essence. We've seen innovations that range from different types of wood particles being used – like bamboo, birch, and even coconut – to advancements in how these filaments can be printed and post-processed. Modern wood filaments offer more durability, a more authentic wooden texture, and are easier to work with than their predecessors.

So, whether you're a seasoned 3D printing enthusiast or just starting, the world of wood filament is an exciting frontier, blending the charm of the natural world with the wonders of modern technology. Let's embark on this journey together, exploring the potential of wood filament to bring our ideas to life in the most beautifully organic way.

Composition and Properties of Wood Filament

In the mesmerizing world of 3D printing, wood filament stands out for its unique composition and intriguing properties. Let's delve into what makes this material tick, the variety it offers, and how it compares in strength and durability to other filaments.

Understanding Wood-PLA Composite Materials

Wood filament is like the perfect blend of nature and technology. It primarily consists of a mixture of PLA (Polylactic Acid) and fine wood particles or fibers. PLA is a popular, biodegradable thermoplastic derived from renewable resources like cornstarch or sugarcane. When combined with wood particles – which can be anything from sawdust to finer wood powders – the result is a filament that boasts the easy printability of PLA with the rustic charm and aroma of wood.

The proportion of wood in the filament can vary, typically ranging from 20% to 40%. This composition results in printed objects that have a wood-like appearance and texture, complete with the organic nuances and grain patterns of real wood. Plus, they often carry a subtle, pleasant woody scent that adds to their allure.

Variations in Wood Content and Their Effects on Print Quality

The percentage of wood content in the filament greatly influences the final print's appearance and characteristics. Higher wood content tends to give a more authentic wood look and feel but can also lead to increased brittleness and complexity in printing. On the other hand, a lower wood content maintains more of PLA’s properties, making it easier to print while still providing a wooden aesthetic.

Different types of wood used in the filament, like bamboo, birch, cedar, or coconut, also impact the final texture and color of the print. These variations allow for a range of creative possibilities, from mimicking specific wood types to experimenting with unique combinations for custom projects.

Comparing Physical Properties: Tensile Strength, Flexibility, and Durability

When it comes to physical properties, wood filament strikes a balance between the characteristics of PLA and the added wood particles. In terms of tensile strength, wood filament generally exhibits good rigidity and sturdiness, but it's not quite as strong or flexible as pure PLA. This makes it more suitable for decorative or non-load-bearing applications.

The flexibility of wood filament is relatively low compared to standard PLA, owing to the added wood particles that make the filament more brittle. As for durability, wood filament printed objects can last quite a while, especially if they are kept away from moisture and direct sunlight, which can degrade PLA over time.

In comparison to other filaments like ABS or PETG, wood filament is less about strength and more about aesthetics. It’s not the go-to for functional parts that require high durability or flexibility, but it's perfect for artistic creations, decorative items, or any project where a wooden look and feel are desired.

So, whether you’re a hobbyist or a professional, understanding these aspects of wood filament can help you make the most of its unique properties, leading to successful and visually stunning prints.

Preparing for Wood Filament Printing

Let's walk through some key steps to ensure you're all set for a successful print, from picking the right kind of wood filament to storing it properly and setting up your equipment the right way.

Selecting the Right Wood Filament Brand and Type

Choosing the right wood filament is like finding the perfect ingredient for a special recipe. You want to look for a brand and type that suit your specific project needs. Each brand has its unique blend of wood and PLA, and the type of wood used can vary greatly – from birch to bamboo, and even exotic types like coconut! Consider what you're aiming to create. Do you want a filament that gives off a strong woody scent? Or are you after a particular wood color or texture? Check out customer reviews and maybe even some online forums. Brands like HATCHBOX and SUNLU often get mentioned for their quality and consistency. Remember, a reliable filament can make all the difference in bringing your 3D printed creation to life.

Storage Techniques to Prevent Moisture Absorption

Wood filament, needs the right storage conditions. Since it's more prone to absorbing moisture (which can really mess with your print quality), keeping it dry is essential. Think of storing it in a cool, dry place, away from humidity. Airtight containers are your best friends here, and tossing in a few desiccant packets can keep moisture at bay. Some folks even use filament dryers or resealable bags with moisture absorbers. The key is to protect the filament from the elements, ensuring it stays in prime condition until you're ready to print.

Equipment Setup: Adjusting 3D Printers for Wood Filament

Setting up your printer for wood filament isn't rocket science, but it does require a bit of tweaking. First, consider the nozzle. Wood filament can be a bit abrasive, so a hardened steel nozzle is a good choice. It's tougher and can handle the wear and tear better than the standard brass nozzle. Next, think about the nozzle size. A slightly larger nozzle, say around 0.6 mm, can help prevent clogs, a common issue with wood filaments due to the wood particles.

Then there's the temperature setting. Wood filament usually prints well at temperatures similar to PLA, but the exact range can vary between brands. Start with the manufacturer’s recommendation and then experiment a bit to find the sweet spot. And don't forget the print bed. A heated bed isn’t always necessary, but if you're using one, setting it to around 50°C to 60°C should work well.

By taking these steps to choose the right filament, store it properly, and set up your printer accordingly, you're laying the groundwork for a smooth and successful wood filament printing experience. Now, let's get that printer warmed up and ready to create some wooden wonders!

Optimal Printing Settings for Wood Filament

Navigating the settings for 3D printing with wood filament can be a bit like tuning a musical instrument. You need the right balance to hit the perfect note – or in this case, the perfect print. Let’s explore how to fine-tune your printer settings, including the extruder temperature, bed temperature, and the print speed and flow rate, to achieve the best results with wood filament.

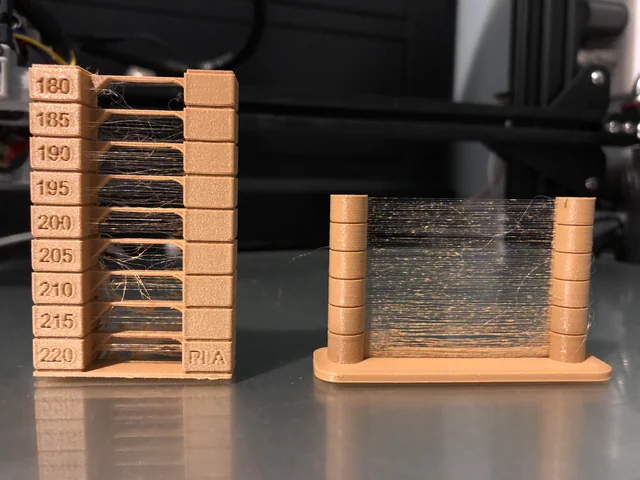

Finding the Ideal Extruder Temperature Range

The extruder temperature is crucial when working with wood filament. It's like finding the perfect cooking temperature – too hot, and you might burn it; too cool, and it won’t cook properly. Typically, wood filament prints well at temperatures ranging from 175°C to 220°C, similar to standard PLA. However, this can vary based on the wood content and the specific brand of filament. Some brands may even recommend pushing the temperature up to 240°C for darker finishes. The key is to start with the manufacturer’s suggested range and then tweak it based on your specific printing needs and the visual and textural qualities you’re aiming for in your print.

Bed Temperature: Necessity and Ideal Settings

When it comes to the bed temperature, think of it as setting the right foundation. For wood filament, a heated bed isn't always a must-have, but it can improve adhesion and the overall quality of the print. If you choose to use a heated bed, a temperature range of around 50°C to 70°C usually does the trick. This range helps the first few layers of your print stick better and minimizes warping, ensuring a smooth and even base for your creation.

Print Speed and Flow Rate Adjustments for Optimal Results

Adjusting the print speed and flow rate for wood filament is a bit like choreographing a dance. You need to synchronize every move for grace and precision. Generally, a print speed of around 40 to 60 mm/s is recommended. Slower speeds can help in achieving better detail and a more wood-like texture, especially for intricate designs. However, you might need to adjust this speed depending on your printer’s capabilities and the complexity of the model you're printing.

Similarly, the flow rate (or extrusion multiplier) might need a slight increase from the standard setting. Some users find that setting the flow rate to about 100% to 110% works well with wood filaments. This adjustment ensures that enough material is extruded, considering the wood particles in the filament can alter the extrusion behavior.

Continuing from our exploration of optimal settings and preparations for wood filament printing, let’s now focus on the crucial aspects of hardware and nozzle considerations, diving into the nuances that make a significant difference in the quality of your prints.

Understanding the Role of Nozzle Material and Diameter

The choice of nozzle material and diameter plays a pivotal role in wood filament printing, much like picking the right tools for a delicate craft. The wood particles embedded in the filament are abrasive, and they demand a nozzle that can endure this roughness without wearing out quickly. A standard brass nozzle, while great for basic PLA, might not stand up to the challenge for long.

On the other hand, nozzle diameter also plays a crucial part. A wider diameter, ideally 0.6 mm or more, provides a smoother path for the wood-infused filament to flow through, minimizing the risks of clogging and ensuring a consistent print quality.

Benefits of Choosing Hardened Steel Nozzles

Hardened steel nozzles are akin to the trusty, durable tools in a craftsman’s kit. When dealing with wood filaments, these nozzles are invaluable. Their robust nature withstands the abrasive quality of the wood particles, ensuring that the nozzle retains its shape and precision over time. This durability means fewer replacements and consistent results in your prints.

However, it's worth noting that hardened steel has lower thermal conductivity compared to brass. This characteristic necessitates a slight increase in the printing temperature, a small adjustment that is well worth the benefits of durability and precision.

Tackling Clogging Concerns with Proactive Measures

Clogging is a common concern when printing with wood filament, but with the right preventative strategies, it can be effectively managed. Regular maintenance of the nozzle is essential. Performing routine checks and cleaning, including the occasional 'cold pull', helps in removing any residual particles that could lead to clogs.

You can follow this comprehensive guide about avoiding and treating with Nozzle clogs. Moisture control is another critical factor. Wood filament is susceptible to moisture, which can cause the wood particles to expand and increase the likelihood of clogging. Proper storage solutions, like airtight containers with desiccants, or using a filament dryer, can significantly mitigate this risk.

Effective Printing Techniques

As we delve deeper into the world of 3D printing with wood filament, let's turn our focus to some effective printing techniques. Mastering these can significantly enhance the aesthetic and functional quality of your prints, making your creations not just good, but great.

Balancing Layer Height for Wood-Like Textures

When aiming for that authentic wood-like finish, the layer height in your print settings is like the fine brushstroke in a painting – it needs to be just right. A lower layer height can provide finer detail, accentuating the wood-like texture of the filament. However, it's essential not to go too low, as this might lead to longer print times and potential issues with clogging due to the filament’s unique composition. Conversely, a slightly higher layer height can speed up the printing process and give a more pronounced 'grain' effect, which can be desirable for certain wood-like aesthetics. Experiment with different layer heights to find the perfect balance for your specific project.

Reducing Stringing and Oozing: Retraction Techniques

Stringing and oozing can be a bit of a nuisance when printing with wood filament, but fear not, as retraction settings are your secret weapon here. Properly calibrated retraction settings can significantly reduce these issues, leading to cleaner and more precise prints. Retraction pulls the filament back slightly when the nozzle moves between printing areas, preventing unwanted filament strands from being left behind. The trick lies in finding the right retraction length and speed for your printer and filament type. Start with the manufacturer’s recommendations and then tweak them based on your print results. A little bit of trial and error can go a long way in achieving string-free prints. You can follow this guide on how to prevent stringing issues while printing.

Temperature Gradients for Color Variation in Prints

Here’s where the magic happens! Wood filament offers the unique ability to vary color shades by simply adjusting the extruder temperature. Higher temperatures tend to darken the filament, mimicking the effect of burnt wood, while lower temperatures yield a lighter hue. You can leverage this property to create prints with natural-looking color variations and gradients, giving a more authentic wood appearance.

Imagine printing a model tree where the trunk gradually darkens towards the base – all achieved through careful temperature adjustments. This technique requires some experimentation and a good understanding of your filament’s behavior at different temperatures. But once mastered, it opens up a realm of creative possibilities, allowing you to add intricate details and lifelike variations to your wood filament prints.

Troubleshooting Common Wood Filament Issues

Just like any adventurous endeavor, 3D printing with wood filament comes with its own set of challenges. But don’t let that dampen your spirit! With a few troubleshooting tips up your sleeve, you can smoothly navigate through common issues like brittleness, warping, and clogging. Let's roll up our sleeves and tackle these head-on.

Managing Brittleness and Material Breakage

Wood filament can sometimes be a bit on the brittle side, especially if it has a high wood content. This brittleness can lead to breakage either during the printing process or in the final print. To manage this, consider tweaking your print settings. Reducing the cooling fan speed can help, as excessive cooling might make the filament too brittle while printing. Also, printing at a slightly higher temperature can make the filament more pliable and less prone to snapping. And let's not forget about post-print care – handle your wood filament prints with the gentle touch they deserve!

Strategies to Overcome Warping and Poor Bed Adhesion

Warping and poor bed adhesion can turn a beautiful print into a frustrating mess. To avoid these issues, first ensure your print bed is clean and level. A clean surface improves adhesion significantly. You might also want to apply an adhesive like a glue stick or blue painter’s tape to the print bed. If you're using a heated bed, setting it to the right temperature (usually between 50°C and 70°C) can also help in keeping the first layers firmly in place. And remember, slower initial layer speeds can aid in achieving better adhesion – patience is key here!

You can follow this article on how to achieve better adhesion

Resolving Nozzle Clogging and Filament Jamming

Clogging and jamming can be a real pain, but they're not unbeatable. One of the best ways to prevent these issues is by using the right nozzle size. As we discussed earlier, a slightly larger nozzle (around 0.6mm or larger) can do wonders in reducing clogs. Regular maintenance and cleaning of the nozzle are also crucial. If you suspect a clog, try the 'cold pull' method to clear out any debris. Additionally, ensuring that your filament is dry before use can prevent jamming caused by expanded wood particles. A filament dryer or airtight storage solutions are excellent tools in this fight against moisture.

Advanced Printing Tips

Once you’ve got the basics down, it's time to elevate your wood filament printing to the next level. Advanced techniques can make a good print great, and knowing how to control moisture, utilize different print modes, and play with temperature variations can add a professional touch to your projects. Let’s dive into these advanced tips that can help you unlock the full potential of wood filament printing.

Moisture Control: Drying Techniques for Wood Filament

Just like real wood, wood filament can be sensitive to moisture, which can affect both its printability and the quality of your final product. If the filament absorbs too much moisture, it can lead to issues like steam bubbles during printing, resulting in poor surface finish and weakened structural integrity. To prevent this, it’s crucial to store your filament properly, ideally in a dry, airtight container with desiccants. But what if your filament has already absorbed moisture? That’s where drying techniques come in. You can use a dedicated filament dryer or a standard food dehydrator to gently heat the filament and drive out moisture before printing. Drying times can vary, but a few hours at a temperature of around 45°C to 55°C usually does the trick. Regularly drying your filament, especially in humid environments, can dramatically improve print quality.

Leveraging Different Print Modes for Unique Designs

Exploring different print modes can open up new possibilities in your designs. For instance, printing in vase mode with wood filament can yield stunning, continuous wood-grain patterns that mimic the look of turned wood. Vase mode works by continuously printing in a spiral, creating a seamless, single-layer thick wall. This mode is excellent for decorative pieces like vases, lampshades, or containers, where the aesthetic of continuous wood grain can really shine.

Incorporating Temperature Variations for Aesthetic Effects

One of the unique aspects of wood filament is how it responds to temperature changes. By varying the temperature during printing, you can create different shades and tones in your print, similar to how wood changes color when burned or stained. This technique requires precise temperature control and a bit of experimentation. You can program your printer to change temperatures at different layers or sections of your print. For example, printing the lower layers at a higher temperature can create a darker base, while gradually reducing the temperature can create a gradient effect. This approach adds depth and realism to wood prints, making them look more like carved or treated wood.

Post-Processing Wood Filament Prints

After your wood filament print has come to life, the journey isn't over yet! Post-processing is where you can really infuse your personal touch and finesse into your creation. This stage is all about refining and enhancing, turning a good print into a masterpiece. Let's explore some effective post-processing techniques that can elevate the appearance and feel of your wood filament prints.

Sanding and Smoothing for a Natural Wood Finish

Sanding is a transformative process for wood filament prints. Just like sanding a piece of actual wood, this step can greatly smooth out the layer lines and imperfections, giving your print a more refined and natural wood-like finish. Start with a coarser grit sandpaper to remove the more prominent lines and blemishes, then gradually work your way up to finer grits for a smooth, polished surface. Sanding not only improves the feel but also prepares the print for further finishing like staining or painting. Remember to sand gently; a little patience here can lead to fantastic results.

Staining and Coating Techniques to Enhance Appearance

Staining your wood filament prints can deeply enhance their aesthetic appeal, bringing them closer to the look of real wood. Choose a stain color that complements your project – maybe a deep mahogany for a classic feel or a light oak for a modern touch. Apply the stain with a brush or cloth, and don’t forget to wear gloves! You might need to apply multiple coats to achieve the desired color depth. After staining, applying a clear coat or varnish can protect the print and add a professional touch. This coating not only preserves the color but also adds a shine, enhancing the overall appearance.

Creative Ideas for Post-Processing and Finishing Touches

Post-processing is a playground for creativity. Beyond the basics of sanding and staining, there are numerous ways to add character and flair to your prints. For instance, you could use a pyrography tool to burn intricate designs onto the surface, adding personalized patterns or textures. Or, try mixing different types of stains for a unique color blend. You can also experiment with different finishes, like a matte or gloss varnish, depending on the look you’re aiming for. Another idea is to combine your wood print with other materials – perhaps adding metal or glass components to create a mixed-media piece.

Creative and Practical Applications

The versatility of wood filament in 3D printing opens up a world of creative and practical possibilities. Whether you're a hobbyist, an artist, or someone who enjoys crafting unique items, the applications of wood filament range from purely decorative to surprisingly functional. Let's explore the varied uses of this material, dive into some inspiring case studies, and discover how it can be combined with other materials for innovative hybrid designs.

Decorative and Functional Uses of Wood Filament

Wood filament's natural, rustic appeal makes it ideal for decorative items. Imagine creating intricate sculptures, detailed models, or personalized home decor items that have the warmth and feel of wood. Picture frames, ornamental boxes, and even custom-made chess pieces or figurines are just a few examples. But it’s not just about looks. Wood filament can also be used for functional objects. Although it may not be as strong as other materials like ABS or PETG, it's suitable for items that don't require high structural integrity. Think along the lines of custom handles, knobs, or even unique light switch covers. The wood aesthetic adds a touch of elegance and warmth that’s hard to achieve with other 3D printing materials.

Case Studies: Innovative Projects Using Wood Filament

There are numerous inspiring examples of projects that showcase the potential of wood filament. For instance, a designer might use wood filament to create a series of intricate plant pots with natural wood grain textures, perfectly blending with their greenery. Another case could involve a hobbyist creating a scale model of a historical building, where the wood filament adds a touch of authenticity to the project. In educational settings, wood filament can be used to create geographical models or historical artifacts, offering a tactile learning experience. These case studies demonstrate not just the versatility of wood filament but also its ability to bring a project's aesthetic and educational value to the next level.

Combining Wood Filament with Other Printing Materials for Hybrid Designs

One of the exciting frontiers in 3D printing is the creation of hybrid objects that combine different materials. Wood filament can be paired with materials like metals, ceramics, or even different types of plastics to achieve unique effects. For example, a designer might print a vase in wood filament and then incorporate a metal filament for decorative accents, creating a piece that juxtaposes the warmth of wood with the coolness of metal. In functional objects, wood filament can be combined with more robust materials for parts that need to withstand stress, while maintaining the aesthetic appeal of wood in less stress-prone areas. The possibilities are nearly endless, limited only by one's imagination and the ability to experiment with different material combinations.

Frequently Asked Questions (FAQs) About Wood Filament 3D Printing

Q1: What is wood filament in 3D printing? Wood filament is a type of 3D printing material that combines PLA plastic with wood fibers. It allows you to create 3D prints with the appearance and texture of real wood.

Q2: Can wood filament be used with any 3D printer? Most 3D printers that can print with PLA filament can also print with wood filament. However, it's important to check your printer's specifications and ensure it can handle composite materials.

Q3: What are the advantages of using wood filament? Wood filament offers a unique aesthetic, mimicking the appearance of real wood. It's ideal for decorative items and can be stained and finished like wood. It's also biodegradable and environmentally friendly.

Q4: Are there different types of wood filament? Yes, there are various types of wood filament available, each with its own wood species and characteristics. Some common options include pine, cedar, and bamboo.

Q5: How do I prevent common issues like stringing and oozing when using wood filament? Properly calibrated retraction settings and experimenting with nozzle and bed temperatures can help reduce stringing and oozing issues. Make sure to follow manufacturer recommendations and adjust as needed.

Q6: Can I create color variations in my wood filament prints? Yes, you can adjust the extruder temperature to create color variations in your prints. Higher temperatures result in darker shades, while lower temperatures yield lighter hues.

Q7: What are some post-processing techniques for enhancing wood filament prints? Post-processing techniques include sanding to smooth out imperfections, staining to enhance appearance, and applying clear coats or varnish for protection and shine.

Q8: Are there any safety precautions to consider when using wood filament? When using wood filament, it's essential to handle it with care, wear appropriate safety gear, and be mindful of potential nozzle clogs and jams. Proper ventilation in your workspace is also advisable.

Q9: Can wood filament be combined with other materials in 3D printing? Yes, wood filament can be combined with other materials like metals, ceramics, or different plastics to create unique hybrid designs that leverage the strengths of each material.

Q10: What are some creative applications for wood filament 3D printing? Wood filament is versatile and can be used to create decorative items like sculptures and home decor, as well as functional objects like custom handles and knobs.

Conclusion

As we wrap up our exploration of wood filament in 3D printing, it's clear that this material offers a fascinating blend of tradition and technology. Wood filament stands out for its versatility, allowing both novices and seasoned 3D printing enthusiasts to create objects with a unique, organic aesthetic. From decorative art to functional household items, the potential applications are as diverse as they are exciting. Looking to the future, we can anticipate further advancements in wood filament technology. Improved formulations may offer even more realistic wood textures and finishes, and perhaps even a broader range of wood types to choose from. We might also see enhancements in filament composition for better printability and strength, expanding the range of possible applications.